Arc Flash

Properly label arc flash hazards in your facility.

Arc flashes and even other types of less serious electrical shocks can cause extremely serious injuries or even immediate death so letting people know where they could happen is essential for any facility.

Emergency Evacuation

Stay prepared for an emergency with visual wayfinding.

Ensure that workers, visitors, and first responders can navigate throughout the facility easily even if the power is down. Evacuation plans and preparations can be the difference between a close call and catastrophic incident.

Foreign Language Labeling

Ensure your entire team understands visual communication.

Visual communication is key to an efficient and productive facility, but it only works if your workforce can understand the information being conveyed. Foreign language labeling ensures that the whole team is properly informed.

Forklift Safety Labeling

Keep your facility safe with forklift safety labeling.

Improve efficiency and productivity by allowing workers to lift heavy materials and cargo. These visual cues you can place in your facility to prevent forklift accidents.

Lockout Tagout Labeling

Keep your machine operators safe with Lockout/Tagout.

Lockout/tagout violations are still among the top ten most frequently cited by OSHA. Keep your employees safe, improve productivity, and cut costs by implementing a Lockout/Tagout safety program.

NFPA Labeling

Lend a hand to emergency responders.

With fire hazards being one of the biggest hazards to workplace safety, companies that comply with NFPA standards are easier to protect for emergency responders, which can further improve safety. By following the codes and standards developed by the NFPA, workers and first responders can easily navigate the emergency safely and efficiently.

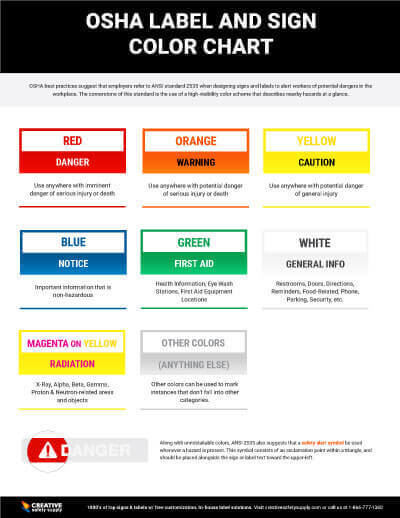

OSHA Labels

Keep your team safe and your facility compliant.

OSHA requires that companies use labels and signs that inform workers of dangers in ways that meet certain standards. OSHA labels will not only help keep your team safe, but also avoid the unpleasant consequences of OSHA violations.

Solar System Labeling

Learn how to properly label your photovoltaic systems.

For solar systems, it’s absolutely crucial that visual communication abide by NEC 2017 div 690, and IFC 2012. These signs must also adhere These energy systems have many components, and each different component requires labels that address appropriate hazard levels.

Wire Marking

Keep your wires and cables organized and efficient.

Wire and cable management is crucial to protecting employees and visitors from electrocution, shock, and other energized hazards. Identifying and organizing cables and wires is crucial to electrical safety, and these wraps are legible and don’t wear easily.

TPM Labels

Enhance your Lean foundation with Total Productive Maintenance.

Remind workers of the 8 pillars of the methodology and implement it alongside a 5S foundation to reduce waste and make your workplace as Lean as possible.

PPE Labels

Remind workers to wear PPE and help them protect themselves against hazards.

When PPE is properly worn, it can defend against illnesses and injuries, even in potentially fatal situations. Use these PPE labels to remind workers that personal protective equipment is required and to indicate which equipment they need to wear for the situation.

Kaizen Labels

Optimize your continuous improvement with Kaizen labels.

Kaizen labels remind all employees to be on the lookout as well, and reinforces the idea that little changes can make a big impact over time.

6S Labels

Enhance the systematic approach to organization in your workplace.

With 6S labels, you can make safety a top priority and make sure that everyone remembers the steps required to a clean workplace.

Electrical Labels

Protect your workers from electrical hazards.

Make sure your workers are safe by labeling electrical equipment and adhering to regulations. These labels are compliant with NFPA and OSHA safety standards, and they effectively communicate important messaging.

Kanban Labels

Transform your workplace with a Kanban inventory system.

Kanban labels enhance communication throughout your facility. They alert workers if action needs to be taken, organize bins and cards, and help clarify what is “To Do,” “In Process,” and “Done.”

Mining & MSHA Labels

Protect miners and stay MSHA compliant with specialized visual communication.

Make sure your mining facility is safe and compliant with labels that adhere to MSHA standards and establish clear, consistent communication in your workplace.

Six Sigma Labels

Implement Six Sigma into your entire facility and achieve black belt status.

Six Sigma labels remind workers of these steps, as well as the corresponding belt levels. Defining, measuring, analyzing, improving, and controlling are easier than ever with a wide variety of communication options that help you prepare your facility for this popular improvement methodology.

Cleanroom Labeling

Straightforward communication prevents cleanrooms from becoming compromised.

Cleanroom labels establish proper procedures and guide workers through necessary tasks; they’ll let workers know what cleanroom clothing to wear and which areas require it. Safety warnings and notice signs clearly communicate how to handle this unique environment.

Circuit Board Labels

Encourage electrical safety and proper identification.

Circuit board labels should be built to withstand harsh environments, as they aid in identifying equipment and are crucial to alerting users to electrostatic damage.

DataCom Labels

Assist the transportation of data to, from, and within your facility.

Data communications involves using communication technology to transport data from point A to point B. It enables the movement of digital data regardless of the contents of that data, your geographical location, or technological method used.

General Identification Labels

Accomplish a variety of labeling tasks with labels designed for general application.

Whether your facility requires a small labeling project or you’re looking to conduct a complete overhaul of your visual communications system, a supply of general identification labels is a great investment.

Inspection and Repair Labels

Keep track of all your inspections and repairs for a smooth operation.

Repair labels indicate whether anything requires renovation and can help your facility stay on top of necessary adjustments and changes. Use Inspection & Repair labels to make records and mark down dates, results, and other information.

Laboratory Labeling

Establish safety and consistency in your labs.

Laboratories require organization and consistent labels to ensure safety. These labels should be resistant to water, oil, acid, and extreme temperatures in order to hold up to the unique environment.

Ratings & Name Plate

Manage data and identification for all the equipment in your facility.

Mark service dates, serial numbers, part numbers, and the logo or name of your company. This way, each piece of equipment is identified and easier to maintain.

Gemba Labels

Help your leaders observe, engage, and improve during their Gemba walks.

Gemba labels tell leaders everything they need to know and help each walk in your facility be performed successfully.

-

Every facility has unique needs when it comes to labeling. Whether it be for OSHA compliance, safety, health, informational, or organizational reasons. We know pre-made labels don’t cut it for some special projects. That’s where our team here... More details

-

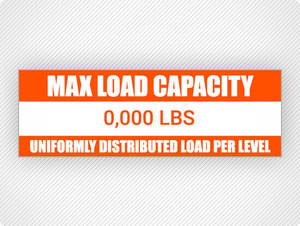

Weight limits are important for forklift operators to know when loading up pallets and shelving units. These labels help prevent overloading, which puts both the operator and other workers at high risk in terms of falling objects or instances of collapse... More details