The prospect of marking all of your facility's pipes can be daunting. There's a steep learning curve, and, since pipe marking is mandatory, there's a lot at stake. Because of that, we've put together a guide that covers everything you need to know about the pipe marking ANSI code, ANSI colors, and all the relevant best practices. This article will also cover the substances that call for special treatment.

For most industries, abiding by ASME/ANSI pipe marking standards will be sufficient for staying safe and OSHA compliant. There are some workplaces, though, that are required to comply with more specific requirements due to the particularly volatile nature of the substances in their pipes, or because of the uniquely complex environment of these workplaces.

Does OSHA Require Pipe Labeling?

Pipe marking is required by law! However, this standard may be hard to find in OSHA’s regulatory documents. That’s because there is no pipe marking section at all. In fact, OSHA uses what is called incorporation by reference to specify labeling codes made by other standard setting organizations. These are often referred to as ANSI codes, ANSI color coding, or the ASME format.

In the beginning of the 1910.6 Incorporation by Reference regulation it states, “The standards of agencies of the U.S. Government, and organizations which are not agencies of the U.S. Government which are incorporated by reference in this part, have the same force and effect as other standards in this part. Only the mandatory provisions (i.e., provisions containing the word "shall" or other mandatory language) of standards incorporated by reference are adopted as standards under the Occupational Safety and Health Act.” While incorporation by reference may seem like mere suggestion at first, it must be known that these types of regulations, often referred to as best practice methods, work exactly the same as the ones that are unique to OSHA. This means companies can still be fined for not complying with regulatory pipe marking standards.

The section that directly refers to pipe marking is as follows, “1910.6(e)(6) – ANSI A13.1-56 Scheme for the Identification of Piping Systems, IBR approved for §§1910.253(d)(4)(ii) [welding and cutting gases]; 1910.261(a)(3)(iii) [pulp and paper]; 1910.262(c)(7) [textiles].” Overall, companies that have piping systems where labeling is necessary are required by law to follow ANSI/ASME 13.1.

So why is pipe marking so important? Best practice methods such as ANSI/ASME 13.1 ensure employees, whether they be maintenance workers or individuals performing tasks in the vicinity, are informed about the dangers around them. Pipes can contain incredibly harmful substances which is why they require pipe markings to let employees and emergency responders know the pipe contents, the direction of flow, and which pipelines contain dangerous substances. Those markings are generally placed on the pipes themselves. Floor signs, since their nature isn’t quite specific enough, are not recommended.

Documentation: Facility Specific Pipe Marking Standards

Once a pipe marking standard has been implemented and established within a facility, it is highly recommended that the employer create a document with all the pertinent pipe marking information for their employees. This can be a book, chart, PDF, or physical sign. Regardless, the documentation should clearly communicate the color meanings, any abbreviations or number sequences, what they are used for, and when they should be used. A set pipe marking code will allow a facility, and all its departments, to have everything they need to make the environment as safe as possible.

Knowing that facilities globally may use varying pipe marking standards, the collective use of a pipe marking key or chart for the benefit of the employees will improve the same core areas of safety. To elaborate, a displayed pipe marking code may help with the following:

- Training: When new employees are brought on board, they must have immediate access to all the necessary pipe marking information. This will keep them safe as well as those around the new employees.

- Reminders: Employers cannot expect every employee to be a star pupil in remembering every single detail about pipe identifiers. Having a key or pipe marking book around will aid their memory. Eventually, those details will be engrained in their brain, making the color code key a gentle reminder in case they forget.

- Safety: Guessing is the exact wrong way to go about identifying pipe contents. Having a facility specific pipe marking code will immensely aid in keeping employees from making assumptions about hazardous materials.

- Standardization: Different departments should not be going by separate pipe marking codes. This can generate confusion between departments and can result in accidents. Standardization, just like beginning a pipe marking program, must follow through and be identical in all departments for safety and clarity.

In the end, having a pipe color code chart for unique facility needs is an absolute must. Think about the pipe marking colors that OHSA purposefully leaves blank for facilities that may need a different class of chemical labeled. Those colors include:

- White text on a purple background

- White text on a gray background

- White text on a black background

- Black text on a white background

When a new employee is hired, they will not know the meanings of these labels since they are facility specific. Do the right thing and implement some kind of pipe labeling key to keep all your workers safe on the job.

ANSI/ASME A13.1 Pipe Labeling Standards

Facilities must follow the general requirements included in the ANSI/ASME 13.1 standard to be compliant with pipe marking standards. The standard itself also incorporates ANSI/NEMA Z535.1 the American National Standard for Safety Colors and the Globally Harmonized System of Classification and Labeling of Chemicals, commonly referred to as GHS.

There are several components that go into properly marking pipes in general use facilities, those being:

- The legend

- The color

- The type and size of letters on pipe labels

- The placement of pipe labels

- Dealing with any abandoned piping

Basic Label Requirements

The legend is an essential segment of the ASME format for pipe marking and identification. In fact, the legend is actually the text on the pipe label itself. All pipe markings need text on the label that gives the reader a clear understanding of what is contained within each pipe. They can say anything from “HOT WATER” to “SULFURIC ACID.” There are also instances where abbreviations are necessary within the text of the pipe label. Remember, notating directional flow is also important for employee safety. Lastly, GHS pictograms are used in pipe markings since they are brief and informative in terms of hazard communication.

Basic Label Body Requirements: Color Code, Sizing, and Label Placement

Color is a particularly important aspect of pipe marking as it provides employees with a quick understanding of the chemical’s potentially hazardous properties. The ANSI colors go as follows:

- Flammable/Oxidizing – Pipes that contains flammable fluids or vapor, or an oxidizing agent, must have a yellow label with black text.

- Combustible – Fluids that have the potential to ignite in the presence of a heat source should use a brown label with white text.

- Toxic/Corrosive – Pipes containing toxic or corrosive fluids should use an orange label with black text.

- Fire Quenching – Water or other fire suppression substances must use a red label with white text.

- Other Water – Any water not intended to be used as fire suppression should use a green label with white text.

- Compressed Air - Any vapor or gas under pressure that doesn’t fit in another category must have a blue label with white text.

As mentioned before, there are also a handful of “user defined” colors that can be taken advantage of within facilities in case there is a substance that does not fit any of the above hazardous categories.

Next, the type and size of lettering on pipe markings must be easily readable. To achieve this, ANSI 13.1 has size specifications that increase alongside the increase in pipe size. It also notes that for pipes less than 0.75” in outer diameter that the pipe be labeled with a permanent and legible tag. The sizing requirements are as follows:

- 0.7” to 1.3” Pipe Width x 8” Label Length = 0.5” Text Height

- 1.4” to 2.4” Pipe Width x 8” Label Length = 0.7” Text Height

- 2.5” to 6.7” Pipe Width x 12” Label Length = 1.3” Text Height

- 6.8” to 10” Pipe Width x 24” Label Length = 2.5” Text Height

- Over 10” Pipe Width x 32” Label Length = 3.5” Text Height

Visibility and frequency of pipe markings is integral to pipe marking strategies which is why placement of these labels is so important. Piping often meanders around a facility with groups of other pipes which can make identification quite difficult. For that reason, ANSI lays out the following requirements for pipe marking labels:

- Pipe labels must be placed above or below the horizontal centerline of the pipe to maximize visibility. This must be done to pipes that are above or below worker’s normal line of vision.

- Pipe labels must be placed near valves and flanges.

- Pipe markings must be placed adjacent to changes in direction, branches, and where pipes pass through walls.

- Labels must be placed at regular intervals on straight runs of pipeline.

What About Abandoned Piping?

Lastly comes the need for dealing with abandoned piping systems. Believe it or not, these also still need to be labeled per the ANSI code. The reason being because oftentimes pressurized fluid is used to protect the inside of the pipe from corrosion, but also there might be some residual hazardous chemicals within the pipe itself. Labeling abandoned pipes is often done with a white label and black text, with the text on the label indicating the contents.

As a reminder, this is a general overview of ANSI/ASME 13.1. If you are looking to start a pipe marking project or fix what you have, it’s best to go over the standard document yourself to make sure you have all the right information.

Ammonia Pipe Marking Standards

Because ammonia is harmful to human health—it is corrosive to the eyes, skin, and lungs—any pipes carrying ammonia-based substances must have more specific labeling than those under the ANSI/ASME standards. The International Institute of Ammonia Refrigeration (IIAR) is responsible for setting standards for ammonia and ammonia pipe labeling.

The standards set forth by IIAR requires facilities to label pipes carrying ammonia-based substances with the following information and color-coding:

- Label Body – The body of the label must be orange with “AMMONIA” in black text.

- Physical State – Use either “LIQ” on a yellow background with black text to denote ammonia in a liquid state or use “VAP” on a blue label with black text for ammonia in a vapor state.

- Pressure Level – Pressure must be labeled “LOW” in green with black text or “HIGH” in red with black text. Pressure over 70 psig is considered high pressure whereas pressure equal to or less than 70 psig is considered to be low pressure.

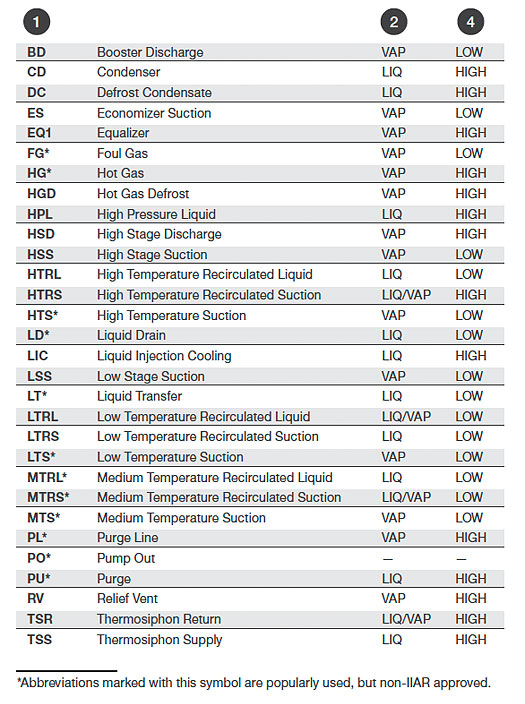

- Abbreviations – Abbreviations can be either an integral part of the ammonia pipe label or be applied separately. The section resides at the very front of the label. The abbreviation is an important piece of information that correlates with the specific purpose of that substance.

- Directional Arrows – These visual components must be black and proportional to the size of the marker.

The chart below lists the common abbreviations for labeling ammonia pipes in accordance with IIAR regulations.

Ammonia is used in a variety of different applications. For example, 87% of the anhydrous ammonia produced is used for crop fertilization, the rest of the 13% is used in various chemical and industrial sectors. Ammonia is also used as cleaning supplies in our homes, as refrigerant, and within plastics production, in explosives, textiles, pesticides, and even dyes. This versatile chemical is necessary for the globe’s way of living, which means the chemical is also mass produced. With that being said, those who handle this chemical need to be safe while doing so, which is why these labeling standards exist.

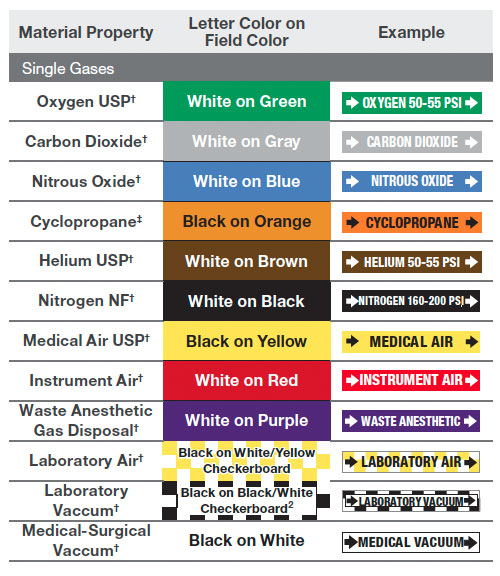

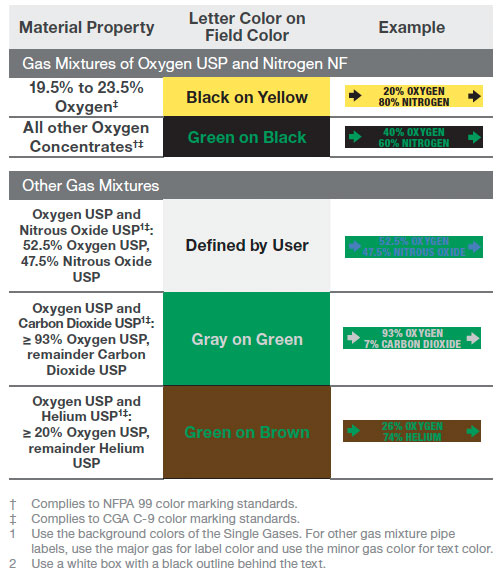

NFPA 99/CGA C-9 Pipe Marking

Substances used for medical purposes have their own standards and best practices as well. Since chemical substances used in hospitals are primarily gases, which are highly flammable, the National Fire Prevention Association (NFPA) is the entity that regulates and sets safety standards. Those labeling methods are used by OSHA to assess compliance.

The NFPA requires that all pipes carrying medical gases such as oxygen, nitrous oxide, and nitrogen in medical facilities be labeled. Not only does this help nurses and doctors correctly identify the type of gas but labeling and following the NFPA color code helps prevent accidents during maintenance work on the gas lines.

Like other labeling standards, the NFPA 99/CGA C-9 pipe marking standard requires labels to include the following information:

- Pipe contents

- Pressure level

- Flow direction

See charts below for NFPA color-coding information, and for specific instructions on gas mixtures.

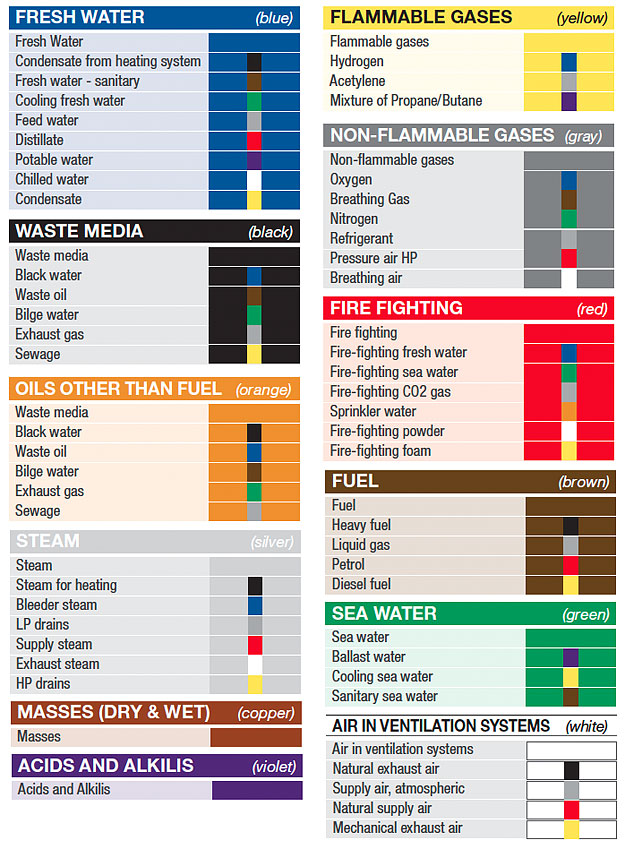

ISO/DIS 14726 Sea Vessel & Marine Pipe Marking

Since marine environments are required to carry fresh water along with gases, waste media, and fire-fighting chemicals, sea-faring vessels must comply with additional pipe marking color codes. This extra effort put into pipe markings for sea-faring vessels provides workers and first responders with the information they need regarding the unique contents of those pipes.

Because vessels travel such vast distances, these codes are internationally recognized. Whether you're docked in Jakarta or passing through the Mozambique Channel, workers and first responders will be able to read your pipe markings easily.

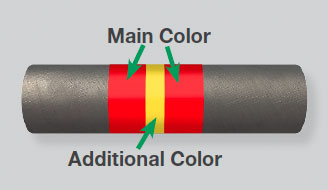

Marine Pipe Marking Standards have main colors, which are defined by ISO 14726 to indicate groups of similar substances. Additional color bars (defined by ISO/DIS 14726-2) are added to indicate specific substances. The additional color should be surrounded by the main color and have a width smaller than that of the main color.

Unlike other standards, Marine Pipe Marking Standards do not require marking pipes for flow direction. Although this is not required, experts strongly advise marking the direction of flow with arrows or arrow-band tape. Additionally, using text where possible can help avoid confusion about the contents of your pipes for someone not yet familiar with the ISO/DIS standards.

Water Treatment Pipe Marking

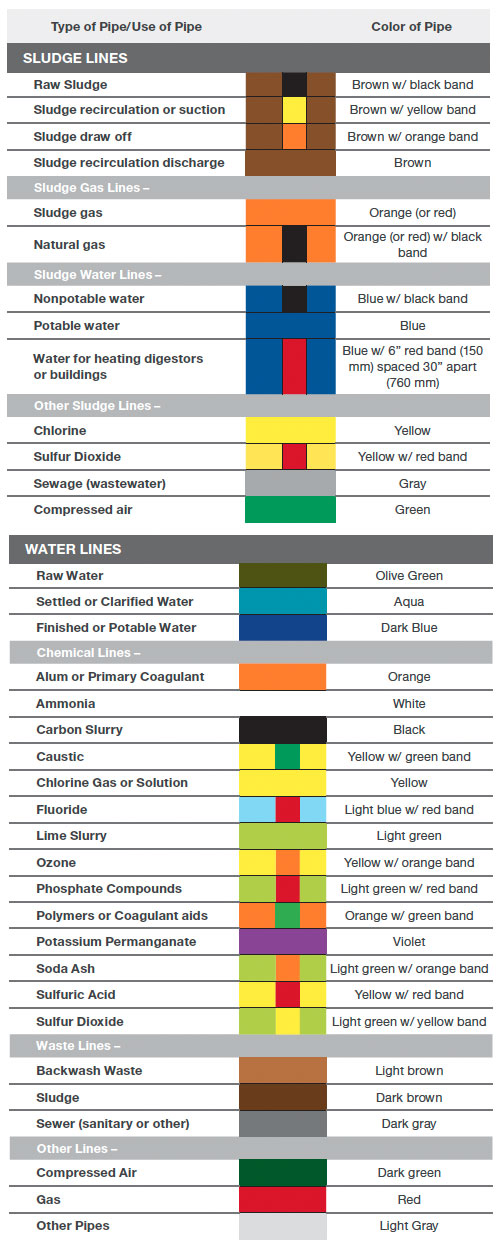

There is a separate guideline for water treatment facilities. Below are some suggestions for labeling water lines, chemical lines, waste lines, and other pipes found in these special environments. The guide shows how pipes should be labeled based on their contents using the corresponding colors.

There are some exceptions to the standards of pipe marking used in water treatment settings. Some states adhere to the 10 States Standards created by the Great Lake-Upper Mississippi River Board (GLURB). If your facility is located in one of these states, you'll want to consult these standards in addition to the guide below. However, if your facility is not within one of these ten states, the ten states standard is still considered to be a best practice method, and therefore many other jurisdictions take advantage of this pipe marking document for water treatment plants.

Commercial Building Pipe Marking

While commercial buildings fall under the ASME/ANSI A13.1 Standard, the additional guidelines listed below will help further identify common pipes found in these facilities. Working much like the marine pipe marking standards, commercial buildings can also take advantage of color bands for pipe labeling.

Make sure to use all of these cheat sheets to pipe marking color codes! They are great tools that can make the labeling task go faster and feel like less of a headache. Labeling your pipes is a large responsibility, but it doesn't have to be a huge burden.

Conclusion

Overall, standardization is key with pipe marking! Without pipe marking best practices from organizations such as ANSI, OSHA, the IIAR, and ISO, pipe identification would be near impossible. Both old and new employees may have a more difficult time transitioning from one workplace with its own set of pipe marking standards to another with a different set of pipe labeling standards.

Do your part in the grand scheme of proper hazard identification and use the best practice methods put forth by these organizations to stay OSHA compliant and keep your employees informed and safe.