Resources

Did you know a worker is injured on the job every seven seconds? That’s approximately 510 injuries per hour, 12,600 in a day, and over 4.5 million occupational injuries a year. Regardless of industry or size, organizations must make safety a priority.

Workplace safety is established through risk assessments, employee participation, hazard controls, safety training, and a strong commitment from management. It is the legal duty (and moral obligation) for employers to create a workplace that employees feel safe and comfortable working in. Focusing on safety can greatly reduce injury and compensation costs, boost morale in workers, and ultimately improve the quality of your organization.

We dive deeper into workplace safety, particularly focusing on:

- Electrical Safety: Working safely with electrical systems, preventing arc flash, properly marking wires, lockout/tagout procedures, etc.

- Forklift Safety: Training and certification requirements, best practices for operators, facility marking for forklifts, etc.

- Fire Safety: Fire prevention plans, floor marking for fire extinguishers, NFPA codes, electrical safety, emergency evacuation, etc.

- Regulations & Compliance: Industry standards coming from the Occupational Safety and Health Administration, National Fire Protection Association, American National Standards Institute, International Standards Association, etc.

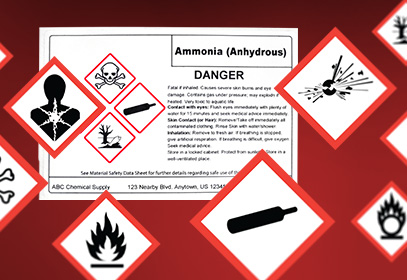

- HazCom: Globally Harmonized System, Hazardous Materials Identification System, SDS/MSDS, NFPA, etc.

As leaders and experts in the safety industry, Creative Safety Supply has compiled all our best safety resources in one convenient location. Whether you need to make your workspace safer or maintain safety procedures, our resources will guide you in the right direction. Find articles, how-to guides, infographics, or browse safety products to get started today.

Getting Started

- Confused with safety acronyms and technical terms? Browse our safety glossary.

- Want to learn more about compliance? Explore our regulations & compliance resources.

- Have a question about safety? Check out our workplace safety Q&A hub.

- Ready to get started? Shop our selection of safety products.

Safety Articles

NFPA 855: The Installation of Stationary Energy Storage Systems

NFPA 855 is an essential standard to follow to maintain worker safety while around stationary energy storage systems. …

Heat Exhaustion and the Dangers of High Temperature Exposure

Learn to recognize the signs and symptoms of heat exhaustion and heat stroke. Heat induced illnesses can cause significant damage to the body and even result in death. …

ISO 45003: Understanding Psychosocial Risks within the Workplace

Learn all about ISO 45003:2021 Occupational health and safety management — Psychological health and safety at work — Guidelines for managing psychosocial risks. …

ISO 31000:2018 – Risk Management

Explore the ISO 31000 risk management guidelines in this article! The principles, framework and process will be gone over in depth. …

Understanding OSHA/ANSI First Aid Kit Requirements

Everything you need to know about first aid kits, where they go, their contents, and why OSHA and ANSI requires them in every workplace. …

Addressing Biohazard Safety in the Workplace

Biohazards consist of bacteria, virus, and fungi pathogens, as well as parasites. Remembering to provide the correct equipment, training, and visual communication is essential. …

OSHA Construction Safety

Construction safety is all about picking out the right PPE, enforcing OSHA regulations, following consensus standards, and creating trust between you and your workers. …

NFPA 25: Standards for Fire Protection Systems

Learn about the updates made to NFPA 25 in 2020 as well as the essential components of fire protection and prevention systems that keep employees safe. …

Understanding Risk Assessments in the Workplace

Risk management relies on specific principles, a framework, and a process to work together in integrating a successful risk management and risk assessment program. …

Understanding the OSHA 300 Log and Other Incident Paperwork

The OSHA 300 log, 300A, and 301 forms are required by law if a company meets certain criteria. These forms enable the recognition of hazards that need to be eliminated. …

Keeping Operators Safe with Machine Guarding

Machine guards are essential for facilities where employees work in close proximity to hazardous moving parts. Properly safeguarding machines prevents severe injury and death. …

Selecting a Marker Size for Wire Marking

An effective wire marking system boosts efficiency and safety in the workplace. This guide helps you determine which marker size is best for the task at hand. …

Fall Protection in the Workplace: OSHA’s Guidelines

Falls are among the leading causes of work-related injuries. Learn about the fall arrest equipment you need and best practices for a fall protection program in your workplace. …

Job Hazard Analysis: Addressing Coronavirus Risk in Your Workplace

A Job Hazard Analysis (JHA) is an effective means of identifying and addressing safety hazards. JHAs can be used to address the risks of COVID-19 in your facility. …

Floor Marking for Social Distancing

Using floor marking materials such as signs, tape, and other visual reminders is a highly effective way to implement social distancing and reduce the spread of illness in your facility. …

Workplace Safety Inspections & Audits

Safety inspections and safety audits are two different methods of continuously improving health and safety in the workplace. Find out which one you need for effective safety management. …

FOD: How to Control and Prevent Foreign Object Debris

FOD is an acronym for Foreign Object Debris and the consequences caused by this debris, Foreign Object Damage. Controlling FOD is critical in both the aviation and manufacturing industries. …

Guide to ANSI/ISEA Z358.1

ANSI/ISEA Z358.1 is the OSHA-enforced standard for eyewash stations and other equipment used to treat the eyes, face, and body of workers who have been exposed to hazardous materials. …

MIL-STD-129: Military Marking for Shipment and Storage

MIL-STD-129 is the U.S. Department of Defense’s labeling standard for the shipment and storage of military equipment. Contractors must use military shipping labels and adhere to other DOD requirements. …

Safety Data Sheets (SDS)

Safety Data Sheets contain crucial information about the classifications and associated hazards of a chemical. They follow a standardized 16-section format and are required for any facility that handles, stores, or transports chemicals. …

Fire Safety in the Workplace

Fire safety is essential in every workplace. These are the principles that will help your facility prepare for fires and prevent them from occurring in the first place. …

6S: Safety

Safety is the additional sixth step to the traditional 5S method. A company that implements 6S focuses on improving organization and efficiency, with an emphasis on safety throughout each step. …

Mine Safety & Health [Expert Advice]

Miners face many hazards that put their safety at risk. By adhering to MSHA standards and providing training and appropriate equipment, employers can enhance mining safety. …

Emergency Spill Cleanup & Containment

When a spill occurs at work, safety relies on a fast response. These are the steps to take and best practices for spill cleanup. …

Title 49: Shipping Hazardous Materials

CFR 49 notes the procedure for transporting hazardous materials safely in compliance with the HMR. Learn more about this important regulation. …

What is Heat Stress?

Are your workers at risk for heat stress? Learn how to prevent this illness and the best plan of action. …

Forklift Safety Procedures

Forklifts are powerful tools that have transformed the way industrial facilities work. With such a powerful tool comes the risk of injury. This article outlines how to increase forklift safety. …

Food Security

With the 2011 passage of the Food Safety Modernization Act, considerable attention has been focused on the purity of our foods from the perspective of accidental contamination. …

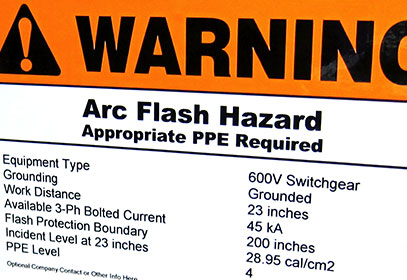

Arc Flash Label Requirements [2018 Updates]

Arc flash hazard labels must be placed on any piece of electrical equipment where workers might need to perform work while the equipment is still energized. …

Behavior-Based Safety

Behavior-Based Safety, when used properly, can increase safety and improve employee engagement in safety programs. Learn how BBS can help you improve your safety program. …

A Quick Guide to Underground Utility Labeling

Underground utility labeling is an essential ingredient to every project that involves construction. This article outlines the step-by-step process of getting your site inspected for utilities, and how to label underground lines safely and accurately. …

Safety Committee

Implementing a safety committee can help improve the overall safety of your company. Discussing safety concerns and resolving them will keep your employees safe. …

Your Guide to Pipe Labeling Standards

If you are looking to implement or update a pipe marking strategy for your facility it is important to gathering as much information as possible. Read More... …

Electrical Wire Colors

Electrical wire colors are essential to the safety of anyone working with electricity. Click here and learn more about electrical color standards. …

OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]

OSHA regulations require businesses to follow one of two safety sign standards to remain in compliance: ANSI 1967 and ANSI 2011. Take a look at these two styles and pick the one that best meets your needs. …

What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

Hazcom is designed to help employees to quickly identify hazardous chemicals. Learn more beneficial information about Hazcom. …

NFPA 70E [Workplace Electrical Safety]

NFPA 70E was created to help prevent injuries to workers in energized environments. If you’re working with live energy, you need to know this safety standard to stay OSHA compliant. …

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

SVEP – Severe Violator Enhancement Program

OSHA’s Severe Violator Enhancement Program (SVEP) was created to help ensure companies actually improve safety practices instead of just paying fines for violations. Learn how to avoid getting this designation by improving your workplace safety protocols and become a safe, efficient facility. …

Waste Water Treatment Labeling

Waste water treatment labeling ensures that all water and flow is accurately labeled. keeping employees safe from contaminated water. …

Neutral Wire Color

Since electricity is an essential component of virtually every facility, it’s important to know which wires are associated with what color, and at what voltage. …

OSHA Accident Reports

All companies want to avoid accidents, but an unfortunate reality is that work-related injuries happen. How a company reacts to the incident is crucial. …

Compliance Audit

Compliance audits are intended to help improve safety both for employees of the company, and for the community as a whole. Learn more about compliance audits how to prepare for them. …

Floor Marking for Facility Safety

The best way to enhance safety is keeping workers informed, and floor markings are the most reliable, durable method of ensuring that everyone is aware of potential hazards. …

Anhydrous Ammonia – Safety & Labeling

Concentrated (or anhydrous) ammonia presents significant hazards to people and the environment. Here’s what you need to know to stay safe. …

Floor Marking for Door Openings

Every time a door opens, it presents a potential hazard to anyone on the opposite side. With careful floor marking, you can massively reduce this risk and prevent numerous injuries. …

Industrial Floor Marking Guidelines

OSHA doesn’t offer much guidance on how floor markings should be installed, so we’ve compiled some helpful tips and best practices to ensure your markings are useful, straightforward, and helpful to everyone in your facility. …

Floor Marking For 5S

Inexpensive yet endlessly practical floor markings can drastically simplify your 5S efforts, while saving you time and money. Learn more in our latest article. …

Electrical Wiring (Wire Color Codes)

Proper electrical wiring is not the place for uncertainity. Fortunately, Wire Color Codes exist to protect you from harm, while ensuring that the lights stay on. …

Hazardous Materials Identification System (HMIS Labels)

Having a complete understanding of the Hazardous Materials Identification System (HMIS) is essential to keeping your employees safe when working with chemicals. …

Floor Marking for Fire Extinguishers

Use floor markings to make sure you can find the fire extinguisher and that it is not blocked in an emergency. …

Occupational Safety and Health Administration

Get answers to the most common questions regarding Occupational Safety and Health Administration (OSHA). …

Hazard Pictograms (GHS Symbols)

More than crude drawings, these nine illustrations protect millions of people throughout a variety of industries each and every day. …

HAZWOPER [OSHA Hazardous Waste Standard]

Crucial training for anyone who works with or near hazardous waste, the HAZWOPER standard seeks to keep workers safe and prevent environmental catastrophe. …

OSHA Card [Program Requirements + Benefits]

The term OSHA Card refers to a type of certification that is issued from OSHA after completing authorized training that they provide. …

Pipeline Labeling

Pipeline labeling is essential when using pipelines in the facility. Without the proper labeling, you are putting your employees at risk. …

Workplace Lifting Safety

Lifting heavy items is one of the leading causes of injury in the workplace. Save time and money by learning how to prevent lifting injuries. …

Crane Safety

Crane safety is essential when working within a construction area. Check out this article for important information and a crane safety checklist. …

Metal-Detectable Labels for FDA Food Labeling Compliance

Accidental contamination is a major worry in the food industry, and while it’s impossible to completely rule out all contamination, metal detectable labels help eliminate a significant danger. …

Forklift Safety

Forklift safety injuries have been on the rise and its up to you to help fix it. Here are some forklift safety tips to help you get started. …

Job Safety Analysis

Job safety analysis is a great process to learn and understand to help identify safety hazards within the workplace. Learn more › …

Creating a Visual Workplace

Creating a visual workplace can help improve efficiency and reduce workplace injuries. Check out these tips for creating a visual workplace. …

Warehouse Management

Proper warehouse management can dramatically improve both efficiency and safety. This article covers everything you need to know. …

Hazardous Waste Disposal

Implementing proper hazardous waste disposal tools within the workplace is essential for keeping employees safe. Do you have these hazardous waste tools? …

Short-Term Exposure Limit

Short-term exposure limits are a guideline that employers can use for how long an employee can be exposed to certain chemicals before their safety is compromised. Find out more... …

Safety Audit

In a safety audit, information is gathered about one or more aspects of the workplace in order to evaluate the risk levels for health or safety issues including efficiency, reliability, and effectiveness of their health and safety systems. …

Planned Maintenance

Planned maintenance, also known as planned preventative maintenance or scheduled maintenance, is an activity where a company will schedule work done in order to avoid outages. …

ANSI S3.19 – Noise Reduction

In most facilities there is no way to eliminate dangerous levels of noise, so it becomes necessary to wear hearing protection. Hearing protection is regulated by ANSI S3.19 standards. …

Visual Factories

Visual factories use signs, posters, charts, labels and floor marking to provide information that improves efficiency, safety and productivity in the workplace. This is a fairly simple concept that yields excellent results. …

Hard Hat Classes [OSHA & ANSI Standards]

Each hard hat class is designed specifically to help provide protection against certain types of hazards. Learn about hard hat classes to ensure the right hats are used to keep everyone safe. …

OSHA 10-Hour Card [Training Requirements]

The OSHA 10 Hour Training program teaches those in attendance all about workplace hazards, the rights and responsibilities of employees and employers, workplace safety, and more. …

NIST Certification / Calibration

NIST is a standards laboratory that is part of the U.S. Department of Commerce that certifies that the equipment used by labs or manufacturing facilities is properly calibrated according to the industry standards in place. …

ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]

ANSI Z87.1 focuses on safety glasses and helps employers and employees make decisions that can help protect people’s eyes and face from a variety of threats. …

Hazard and Operability (HAZOP Analysis)

When done properly, the HAZOP process will identify potential design or process flaws that were not discovered in the past. …

OSHA General Duty Clause

The OSHA General Duty Clause is in place to require that employers provide employees with a workplace free from any recognizable hazards that could put them at risk of death or serious injury. …

Ammonia Refrigeration

When using ammonia refrigeration, or ammonia for anything in the workplace, there are a variety of OSHA regulations that need to be followed. …

Fire Prevention in the Workplace [OSHA 1910.39]

Fire prevention safety is important for all employees and workplaces. This article explains fire prevention standards and provides helpful tips. …

OSHA Safety Sign Requirements [1910.145]

Understanding OSHA standards for warning signs and tags is an essential part creating a safe work environment. …

ANSI Color Codes for Pipe Marking

When following the ANSI A13.1 standards, the most important thing is to understand the six most common color schemes. …

OSHA Ear Protection Requirements (Standards for Hearing Safety)

Many people don't think about hearing protection when we talk about safety, but hearing injuries are one of the most common types of injuries that occur in the work place. …

Floor Markings for Forklift Safety

Installing floor markings for forklift traffic can help improve safety and efficiency in warehouses and factories. Take these steps to keep employees safe. …

Understanding the NFPA 704 Diamond Labeling System

Learn how to properly label hazardous materials following NFPA 704 labeling standards. …

5 Lean Manufacturing Tools that Work

These five lean manufacturing tools are essential for making your lean journey a success. …

Floor Marking Ideas for Warehouses

Warehouse floors provide an opportunity for visual communication. Find out what floor signs, tapes, and shapes you can use. …

Typical Lockout Tagout Procedures

Find out how to use lockout tagout procedures for different kinds of energy including electrical, chemical, and pneumatic. …

GHS Label Information

A closer look at OSHA’s Hazard Communication Standard—1900.1200—and how it applies to your facility. …

Types of Floor Marking

Many options exist for marking floors. Learn about floor tapes, virtual floors signs, and more. …

Confined Space Hazards

When is it safe to work in a confined space? Get the details in this article. …

Arc Flash and Electrical Safety

Learn how arc flash works and how it relates to your larger electrical safety program. …

Lockout/Tagout Program (How To Control Hazardous Energy)

Understand the basic requirements for preventing the accidental startup of equipment during maintenance. …

Safety Colors (OSHA Guidelines and Color Codes)

Using colors strategically makes communication in your facility more effective. Get the details about common color codes. …

Arc Flash PPE

Make sure everyone knows what protective equipment they need to work near this serious hazard. …

ANSI Z535 [Updated Guide to Safety Signs & Labels]

An in-depth look at ANSI’s standard for safety signs and labels in the workplace. …

15 Forklift Safety Tips [Industry Expert Advice for Safe Operation]

This helpful list for drivers provides 15 practical tips for safe forklift operation. …

Floor Stickers – Your floors come alive and speak

Improve safety in your workplace by using these 10 types of floor signs. …

Washington State – Accident Prevention Program

Find out the basic requirements of an accident prevention program. Then learn how to implement or improve one. …

PPE: Personal Protective Equipment [Safety Standards]

Get an overview of common PPE requirements for the workplace including breathing protection, eye protection, and more. …

Valve Tags: Guide for Pipe Identification

Tips and recommendations for labeling the valves on your pipe system. …

10 Essential Steps for Electrical Safety

Follow these 10 steps to protect people and property from electrical hazards. …

Arc Flash Software helps improve Arc Flash Safety

A review of common software programs that will help you reduce arc flash hazards. …

Aisle Marking Tape – 5 Strongest Tapes You have Ever Seen!

Learn the requirements for marking aisles and the best methods for doing so. …

The Definitive Guide to Globally Harmonized System (GHS) Labeling

Implementing GHS has been an evolving process for many companies. Here's what you need to know. …

Hierarchy of Controls [Hazard Exposure + Prevention]

An explanation of the best ways to mitigate hazards: elimination, substitution, engineering controls, administrative controls, and PPE. …

Material Safety Data Sheets [How-To Guide for Upgrading to SDS]

Learn the difference between the old material safety data sheets and the new GHS/HazCom safety data sheets. …

Pipe Color Codes - ANSI/ASME A13.1

The ANSI/ASME A13.1 pipe marking color code explained. …

OSHA Facts

Everything you need to know about the Occupational Safety and Health Administration. …

Arc Flash [Facts, Safety Requirements & PPE]

Arc flash can cause serious damage to people and property. Learn how arc flash works and how you can prevent it. …

OSHA Floor Marking

Find out what OSHA has to say about marking your facility's floors. …

Process Safety Management

PSM is an OSHA standard developed for companies that handle hazardous chemicals. …

Cable Management

Properly marking wires can improve organization, facilitate faster maintenance, increase safety, and more. …

GHS Label Creation

Find out how to make Globally Harmonized System (GHS) labels in 3 steps. …

Floor marking comprehensive research, education and training

Everything you need to know about marking your facility’s floors. Types of markings, practical tips, and more. …

Safety Questions and Answers

Where should emergency eye wash stations and showers be located?

Facilities must not only be equipped with the right emergency features, but they must be installed to provide employees with the quickest and greatest relief from contaminants. OSHA refers to the ANSI/ISEA Z358 standard when to comes to addressing minimum selection, installation, operation, and maintenance requirements for eye wash equipment and emergency safety showers. The first step… …

What is the NSC?

The NSC is the National Safety Council, a nonprofit organization that has been a leading advocate for safety since its founding in 1913. Its mission is to reduce the number of preventable deaths that occur in the U.S. Although the Council has several areas of focus, including eliminating preventable deaths that occur in communities, at… …

What is PSM?

PSM is process safety management, a standard that was created by OSHA to prevent the release of highly hazardous chemicals and, in the event that an accidental release does occur, helps to minimize the consequences. A facility that correctly implements the PSM standard actively works to prevent disasters that concern dangerous substances through communication, training,… …

What does EHS stand for?

EHS stands for Environment, Health, and Safety. Companies in a variety of industries have adopted EHS programs that not only ensure employees are safe at work, but also ensure that the quality of the environment and the health of the local community are protected from any hazards or consequences of the company’s operations, such as… …

![Mine Safety & Health [Expert Advice]](https://www.creativesafetysupply.com/content/images/articles/mining-safety-th.jpg)

![Arc Flash Label Requirements [2018 Updates]](https://www.creativesafetysupply.com/content/images/articles/arc-flash-labels-th.jpg)

![OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]](https://www.creativesafetysupply.com/content/images/articles/ansi-sign-headers-th.jpg)

![NFPA 70E [Workplace Electrical Safety]](https://www.creativesafetysupply.com/content/images/articles/nfpa-70e-th.jpg)

![HAZWOPER [OSHA Hazardous Waste Standard]](https://www.creativesafetysupply.com/content/images/articles/hazwoper-thumb.jpg)

![OSHA Card [Program Requirements + Benefits]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-osha-10-card.jpg)

![Hard Hat Classes [OSHA & ANSI Standards]](https://www.creativesafetysupply.com/template/images/articles/hardhat-classes-thumb.jpg)

![ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ansi-safety-glasses.jpg)

![Fire Prevention in the Workplace [OSHA 1910.39]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-fire-prevention.jpg)

![OSHA Safety Sign Requirements [1910.145]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-warning-signs-tags.jpg)

![ANSI Z535 [Updated Guide to Safety Signs & Labels]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ansi-z535.jpg)

![15 Forklift Safety Tips [Industry Expert Advice for Safe Operation]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-forklift-safety.jpg)

![PPE: Personal Protective Equipment [Safety Standards]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ppe.jpg)

![Hierarchy of Controls [Hazard Exposure + Prevention]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-hierarchy-hazards.jpg)

![Material Safety Data Sheets [How-To Guide for Upgrading to SDS]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-msds-sds.jpg)

![Arc Flash [Facts, Safety Requirements & PPE]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-arc-flash-facts.jpg)