Resources

Whether your jobsite is under overhead powered lines or your facility has high-voltage equipment, electrical safety must be a priority for every workplace. The risk of injury from electricity can be severe – causing shock, burns or even death, and faults can easily result in destructive fires or explosions.

OSHA has long recognized electricity as a serious workplace hazard with their electrical standards which are largely based on the National Electric Code (NFPA 70) and NFPA 70E, entitled Electrical Safety Requirements for Employee Workplaces. OSHA requires employers to safely install electrical systems, train for qualified personnel to work with electricity, provide appropriate PPE at no cost, and above all else, identify and address all electrical hazards.

In our electrical safety resource hub, we cover many facets of electrical safety, including:

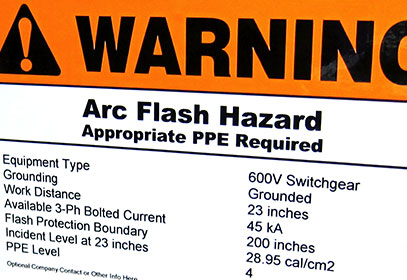

- Arc Flash: Out of all electrical hazards, the biggest risk is that an arc flash will occur. Arc flashes are an electrical explosion that can cause severe injury or death.

- Equipment Labeling: Regulations mandate high-voltage machines and equipment with the potential to cause an arc flash to be labeled.

- Lockout/Tagout: The OSHA standard for properly controlling hazardous energy as well as the most effective way to prevent arc flash.

- Solar Power: Solar powered systems doesn’t operate like your typical electrical system, so it’s important to understand their unique safety requirements.

We cover everything thing you need to know to keep your facility safe from electricity – prevention, protection, emergency procedures, and so much more. Whatever your electrical safety goal is, we’re here to help.

Getting Started

- Confused about electrical standards? Check out our list of regulations and industry standards.

- Want to learn more about arc flash? Explore our arc flash resources.

- Have a question about electrical hazards? Browse our electrical safety Q&A hub.

- Ready to get started? Shop our selection of electrical safety supplies.

Electrical Safety Articles

NFPA 855: The Installation of Stationary Energy Storage Systems

NFPA 855 is an essential standard to follow to maintain worker safety while around stationary energy storage systems. …

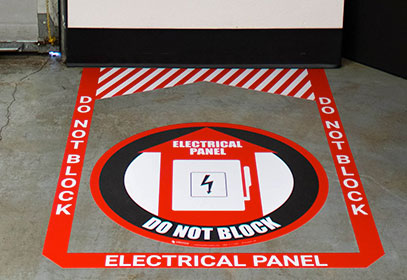

Floor Marking for Electrical Panel Compliance

Meet OSHA requirements for electrical panel clearance with floor markings! Creative Safety Supply offers a wide selection of floor signs and floor tapes for breaker panels. …

Improving Workplace Electrical Safety

Choosing to improve worker knowledge and equipment for electrical safety creates a much safer workplace and improves overall productivity. …

Heat Shrink Tubing

Heat shrink tubing and wire markers are excellent visual organization tools. They are cost effective and improve productivity and efficiency within the workplace. …

Selecting a Marker Size for Wire Marking

An effective wire marking system boosts efficiency and safety in the workplace. This guide helps you determine which marker size is best for the task at hand. …

National Electrical Code (NEC)

The National Electrical Code (NEC) is the ANSI/NFPA-approved standard for safe electrical installation. The NEC is revised once every three years, with the most recent changes in 2017. …

Arc Flash Label Requirements [2018 Updates]

Arc flash hazard labels must be placed on any piece of electrical equipment where workers might need to perform work while the equipment is still energized. …

Electric Arc [Definition, Applications & Arc Flash]

Electrical arcs can be a serious hazard when not intended. When an electric arc is created in an uncontrolled environment, such as an arc flash, serious injury or death can occur. Learn more... …

Electrical Wire Colors

Electrical wire colors are essential to the safety of anyone working with electricity. Click here and learn more about electrical color standards. …

NFPA 70E [Workplace Electrical Safety]

NFPA 70E was created to help prevent injuries to workers in energized environments. If you’re working with live energy, you need to know this safety standard to stay OSHA compliant. …

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

ANSI TIA 606-B Cable Labeling Standards

ANSI TIA 606-B Cable Labeling Standards are a unified labeling method for the wires used in computer systems. These standards help businesses record data and keep their IT environments organized. Get to know these standards; they’ll help your business run more efficiently. …

Neutral Wire Color

Since electricity is an essential component of virtually every facility, it’s important to know which wires are associated with what color, and at what voltage. …

Solar System Labeling

In 2017, The National Electrical Code (NEC) made some significant changes to solar system labeling standards. Getting familiar with these updates will help your facility stay safe and efficient. …

Electrical Wiring (Wire Color Codes)

Proper electrical wiring is not the place for uncertainity. Fortunately, Wire Color Codes exist to protect you from harm, while ensuring that the lights stay on. …

Labeling Electrical Conduits

Learn how to label electrical conduits so employees can quickly identify them. …

Typical Lockout Tagout Procedures

Find out how to use lockout tagout procedures for different kinds of energy including electrical, chemical, and pneumatic. …

Arc Flash and Electrical Safety

Learn how arc flash works and how it relates to your larger electrical safety program. …

Lockout/Tagout Program (How To Control Hazardous Energy)

Understand the basic requirements for preventing the accidental startup of equipment during maintenance. …

Arc Flash PPE

Make sure everyone knows what protective equipment they need to work near this serious hazard. …

10 Essential Steps for Electrical Safety

Follow these 10 steps to protect people and property from electrical hazards. …

Arc Flash Software helps improve Arc Flash Safety

A review of common software programs that will help you reduce arc flash hazards. …

Floor Marking for Electrical Panel Compliance

Make sure you are meeting OSHA requirements for marking around electrical panels. …

Arc Flash [Facts, Safety Requirements & PPE]

Arc flash can cause serious damage to people and property. Learn how arc flash works and how you can prevent it. …

Cable Management

Properly marking wires can improve organization, facilitate faster maintenance, increase safety, and more. …

Electrical Safety Questions and Answers

What are Some Tips for Working with Power Cords?

Most people don’t give much thought to power cords, but when it comes to optimizing the way a workplace operates, they deserve some attention. Read through a variety of tips for working with power cords to ensure your facility is using them properly. To start with, you want to make sure that all power cords in… …

Who Regulates the Labeling Standards for PV Systems?

When installing or upgrading any type of photovoltaic (PV) system, you need to make sure that everything is set up and configured properly. This, of course, starts with making sure that the system itself is handled correctly, but you also need to make sure that you have the proper safety requirements in place. This means… …

What are Solar Photovoltaic (PV) Labeling Requirements?

The use of solar panels in both residential and commercial environments is growing quite rapidly. Over the years, these solar photovoltaic systems have been installed on roofs, in open fields, and even over large bodies of water. Along with the growth in popularity of these systems came several important regulatory requirements to help ensure they… …

Where Should Solar PV Labels be Installed?

When installing a solar PV system, you need to make sure that you have all the key components labeled properly. This will not only help ensure the system is safer to work with, but will also provide important information to anyone performing maintenance on it down the road. As with all electrical systems, there are… …

What are Distribution Boards?

A distribution board is a part of an electrical system that takes electricity from a main source and feeds it through one or more circuits to distribute the electricity throughout a facility. This is often called an electrical panel, panelboard, or even a fuse box. Virtually all homes and businesses will have at least one… …

How to Paint an Electrical Panel Cover?

If you have an older electrical panel that is scratched up or otherwise not looking good, you may want to give it a fresh coat of paint. Some facilities will even want to paint their electrical panel to get it to match the walls around it when they are painted a new color. It is… …

What is the Voltage of a Neutral Wire?

This is a common question that one would think should have a simple answer, but that is not actually the case. The neutral wire is often said to have zero voltage on it. If you touch that wire on a live system, however, you will often find out very quickly that technically having zero voltage… …

What Levels of Voltage are Lethal?

This is a very common question, but the answer is not as clear as many people would hope. The amount of voltage it will take to kill a person will vary greatly based on many different factors. For example, it takes very little electricity to kill someone if it is applied directly to the heart.… …

Who Regulates Electrical Panel Labeling?

Electrical panels represent one of the most important, but also most dangerous, items in any facility. When installed, managed, and labeled properly, they can work for years without problems and cause very little risk to those who work with or around them. If, however, a company fails to label them or does something else that… …

What are the Requirements for Labeling Circuit Breakers?

When thinking about labeling circuit breakers, most people assume that the only reason to do it is to make sure you can tell what breakers go to what part of the facility. The reality is, however, that there are quite a few regulatory requirements in place regarding what labels need to be there and how… …

Does an Electrical Panel Need a Cover?

The regulations related to electrical panels can be quite confusing, especially when it comes to the cover of the panel. Many people believe that all electrical panels must have a front cover or door on them, but that is not actually the case. Interestingly, most regulations only say that these panels need to have a… …

What Type of Labels are Used for Electrical Panels?

When labeling your electrical panel it is not enough to just have labels with the proper information on them. You actually need to use the right type of labels in order to get the results that you are looking for. Since electrical panels have electricity flowing through them, it is necessary to use a labeling… …

Why is Electrical Panel Labeling Important?

Labeling your electrical panel is more than just a convenient idea. It is actually a regulatory requirement in many situations. This is especially true when it comes to industrial facilities that use a lot of high voltage equipment. Proper labeling will provide your business with a lot of major benefits on top of the fact… …

What are the Requirements for Electrical Panel Labeling?

There are quite a few different requirements that a business needs to be aware of when labeling their electrical panels. The specific requirements will vary quite a bit based on local and state laws, though there are also some federal laws and best practices that should be followed in order to keep the facility safe.… …

What are the Minimum Clearance Requirements for Electrical Panels?

When installing or updating an electrical panel, it is important to make sure that there is plenty of room around the panel for the electrician to safely work. This is why OSHA has put a requirement that all electrical panels have a minimum of three feet (36 inches) of room from the front of the… …

What is an example of an electrical safety checklist?

Dangerous electrical hazards are present whether you work in a small office or a large construction site. When it comes to avoiding arc flashes and preventing electrical related injuries, you must first take a thorough assessment of the workplace. Below is an example of a basic electrical safety checklist that can be followed to eliminate electrical… …

What is meant by safety & health in the workplace?

When most people refer to health and safety efforts in the workplace, they primarily target eliminating workplace hazards to keep people safe from harm. However, the World Health Organization directly states that, “Health is a state of complete physical, mental, and social well-being and not merely the absence of disease or infirmity.” This infers that… …

What is the most common OSHA electrical violation?

According to OSHA’s top ten most cited safety violations in 2020, the most frequently cited electrical violation was the inability to control hazardous energy. In the industrial world, controlling hazardous energy is bundled together with the use of a Lockout Tagout program. Due to the safety implications that electricians and other workers face in electrified… …

What are electrical safety devices?

Electricity is everywhere! It powers our kitchen appliances, entertainment systems, computers, water heaters, hairdryers, and countless other necessities in our homes. However, when improperly managed, electricity can be dangerous. It can cause fires and electrocute workers and homeowners, all of which can ultimately lead to serious injury or even death. Thankfully, there are a handful… …

What are electrical safety audits?

Electrical safety audits must be performed on a regular basis for all electrical safety related programs within a workplace. More specifically, field work audits must happen yearly, and electrical program reviews must occur every three years or less. The three-year review gives the employer a chance to find outdated aspects of the safety program that… …

What is the need for isolation in electrical equipment?

Isolation in electrical equipment, also known as power supply isolation, is primarily concerned with providing a means of separation between two circuits. While still enabling a power transfer from both electric components, electronic isolation prevents the transfer of alternating current and direct current to other parts of a system where it’s not wanted. By separating… …

What are the differences in voltage between the U.S. and Europe?

Those who travel may run into the problem of not only needing adapters for their electrical plugs but also needing to be extra cautious of what their appliances take in regard to voltage. North America and a few others such as Japan are some of the few countries that use a different quantity of voltage… …

What are European electrical standards?

European electrical standards are only a small segment of the vast number of European Standards, or EN, that exist to keep citizens safe from harm. European electrical standards are created and approved by one of the three European Standards Organizations: CEN, CENELEC, or ESTI. To put it simply, everyone knows there are different plugs and different… …

What is ESD?

Electrostatic discharge, commonly referred to as ESD, is the spontaneous flow of energy between two objects when both have been electrically charged by static electricity, electrostatic induction, or in some cases electrically charged particles striking an object. These types of energy transfers have been around since the beginning, but ESD has only become an issue… …

What does NEC stand for?

The NEC is the National Electrical Code, a global standard for the safe installation of electrical wiring and equipment. Formally identified as ANSI/NFPA 70, the NEC establishes the basis for electrical safety in residential, commercial, and industrial buildings. Every electrician should be familiar with the NEC’s standards; licensed electricians are taught the Code during classroom… …

What does ESD stand for?

ESD is an acronym for electrostatic discharge. This discharge is the rapid transfer of static between two different objects. Although ESD doesn’t typically cause harm to the human body—you might only experience it as a small, surprising shock—it can cause extensive damage to electrical equipment and sensitive instruments. This damage may either be permanent and… …

What does IEC stand for?

IEC stands for International Electrotechnical Commission. It is a group that develops standards that are used in countries around the world. These standards are focused specifically on electrical, electronic, and other related topics, which they sum up as ‘electrotechnology.’ The IEC can trace its history back to 1881 when the first International Electrical Congress took… …

What does NEMA stand for?

When discussing manufacturing, construction, and other related industries, the acronym NEMA stands for National Electrical Manufacturer Association. They were initially founded in 1926 when the Associated Manufacturers of Electrical Supplies and the Electrical Powers Club merged. They began monitoring the quality and safety of various electrical products, and also created a process to help ensure… …

What electrical safety training should I provide?

Keeping employees safe at work is one of the primary obligations that a company has toward their workers. When working with electrical systems, this is especially important because of the fact that electrical injuries can cause permanent damage or even death in an instant. With this in mind, a company should always have a comprehensive… …

What are common hazards when working with electricity?

Electricity is one of the most dangerous forces of nature, yet we harness and use it every day to power homes, businesses, vehicles, and more. Whenever working with electricity, it is important to respect how dangerous it can be, and take steps to reduce the risk of accidents and injuries. One of the easiest things… …

How can a LOTO program improve electrical safety?

The lockout-tagout (LOTO) program is one of the most important ways that companies can improve safety when working on electrical system. The concept behind LOTO is that anyone who will be working on an electrical system has to physically remove the source of electricity, and place a lock on it so that it can’t be… …

What are electrical safety standards and who enforces them?

There are many different electrical safety standards that need to be followed in the workplace. These standards are often developed by safety companies, governmental agencies, or others that work to find the best practices in given situations. Some of these standards are enforced by government agencies, such as OSHA, and can come with serious penalties.… …

What are electrical wire colors?

When installing or working on electrical equipment it is important that all the wires are connected correctly. To make this easier, there are color standards for different types of wiring and what they are used for. This can be helpful in any situation, but is especially critical in equipment where the wires are long and… …

What are supplies I should have on hand to prevent or respond to electrical hazards?

All modern facilities use electricity to power their machinery and other equipment. In most cases, these items use high-voltage electrical currents, which can be very dangerous if there is any type of problem. With this in mind, employees need to be trained and equipped to be able to prevent electrical problems from occurring, or to… …

How often should electrical safety training be offered?

Providing electrical safety training to your employees is a proven way to minimize the risks of shock, fire, arc flashes, and other dangers. This type of training can cover general information about the hazards of electricity, how to work with it, and specific information about how your facility is to operate. The problem can be that… …

How should electrical panels or conduits be marked?

Electrical panels and conduits in many facilities have massive amounts of electricity flowing through them. These are typically the places where the main sources of electricity comes into the building, and where all equipment in the facility needs to be connected in order to access it. This makes these areas among the most dangerous when… …

How does electrical shock occur and how can it be prevented?

Electricity represents a huge danger to virtually every workplace, and those who are employed there. When someone is shocked due to an electrical problem it can range from a mild injury to a fatal accident, and everything in between. Learning how shocks occur, and how to prevent them, is a key component of any workplace… …

How do electrical fires start and how can they be prevented?

Electrical fires are account for 6.3% of residential fires, and many industrial fires as well. Using electricity is required for modern living, so it is important to identify the causes of these types of fires, and what can be done to prevent them. In the workplace, these types of fires can cause millions in damage,… …

What is common PPE used for electrical safety?

The best way to keep people safe from electrical hazards in the workplace is by implementing policies and procedures that reduce or eliminate various risks. Unfortunately, it is impossible to take steps that can be 100% effective, and if there is even one incident it can be deadly. With this in mind, it is important… …

How can visual communication improve electrical safety?

Electrical safety in the workplace is extremely important because electrical accidents can happen so quickly, and the results can be devastating. Without proper precautions, people can be killed due to electrocution, fires can be started, and even explosions can occur. One proven way to improve the safety of the workplace is to use visual communication… …

What Does it Mean to be Compliant for Electrical Safety?

Keeping the workplace safe from electrical hazards is the responsibility of everyone who is in the facility. Whether it is a manufacturing facility, a laboratory, an office, or some other environment, electricity is both very useful and very dangerous. This is why companies work to ensure they are compliant for electrical safety. Understanding what this… …

What are electrical safety risks in the office?

Compared to many other industries, office environments are fairly safe. There are still thousands of injuries that take place in office environments, but most of them are related to falls and other similar accidents. Just because an office is typically quite safe, however, doesn’t mean that the existing hazards should be ignored. Electrical hazards are… …

What are electrical safety risks at a construction site?

There are many hazards on a construction site, which is why contractors and construction companies take workplace safety seriously. While there are many different dangers to be aware of, few of them are as serious as the risk of problems caused by electrical systems. Throughout the entire work site there are going to be a… …

What are electrical safety risks in a lab?

When working in a laboratory environment most people don’t give much thought to the electrical systems that are present. While electricity is certainly used in almost all areas of a lab, there aren’t usually wires run all over, or even high-voltage signs displayed like you would find in many other environments. That being said, however,… …

Why is electrical safety important?

Workplace safety is something that every company needs to make a top priority. There are many types of hazards that exist, and in general they are all just covered under the generic topic of workplace safety. Interestingly, electrical safety is often addressed separately by many businesses. Some people wonder why electrical safety is so important,… …

What are electrical safety measures?

In any workplace it is important to take proper electrical safety measures to help avoid any type of accident or injury. This is especially critical when it comes to facilities with high voltage machinery and other equipment. The following are some basic electrical safety measures that should be put in place at virtually every facility.… …

What are electrical safety tips?

When trying to improve the safety of a facility there are many approaches that can be taken. One option is to conduct in-depth training courses, and engage in large scale activities focused on electrical safety. While that can certainly be effective, it is also a good idea to look into smaller-scale options that are more… …

What are the basics of electrical safety?

Electricity is required for just about all types of activities in most manufacturing and other facilities. For the last century, electricity has been a crucial part of just about everyone’s day to day life both at home and in the workplace. While electricity has improved the world in many ways, it is still important to… …

![Arc Flash Label Requirements [2018 Updates]](https://www.creativesafetysupply.com/content/images/articles/arc-flash-labels-th.jpg)

![Electric Arc [Definition, Applications & Arc Flash]](https://www.creativesafetysupply.com/content/images/articles/electrical-arc-th.jpg)

![NFPA 70E [Workplace Electrical Safety]](https://www.creativesafetysupply.com/content/images/articles/nfpa-70e-th.jpg)

![Arc Flash [Facts, Safety Requirements & PPE]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-arc-flash-facts.jpg)