Resources

Before President Nixon signed the Occupational Safety and Health Act of 1970, workers were not afforded the right to a safe workplace, often leaving them with the difficult choice of risking their health working in hazardous conditions or leaving a job with a steady paycheck. In the decades since, OSHA has transformed the landscape of workplace safety – dramatically reducing the number of workers killed on the job and holding employers accountable for safe jobsites.

So, what does OSHA do?

- Rights & Responsibilities: Employees are guaranteed the right under OSHA regulations to working conditions that do not pose a risk of serious harm. Employers on the other hand, are responsible for a workplace “free from recognized hazards that are causing or are likely to cause death or serious physical harm.”

- Health & Safety Standards: OSHA’s standards are law, and Businesses must comply with all applicable OSHA standards to protect their employees from workplace hazards.

- Inspections + Enforcement: OSHA inspections are an important component of reducing workplace injuries, illnesses, and fatalities; in 2018 alone, OSHA conducted more than 30,000 inspections. A compliance officer shows up to facilities, typically unannounced, tours the workplace, and at the end issues any citations for violations found. Penalties can be hefty and ongoing until the hazard has been properly addressed.

- Whistleblower Protection: Employees are protected from retaliation under OSHA’s Whistleblower Protection Program. Anyone who files a complaint with OSHA is protected from any negative consequences brought upon by their employer (firing, demoting, reducing pay, etc.).

At Creative Safety Supply, we are dedicated to helping organizations meet compliance and improve safety. Below we have gathered our expert resources on all things OSHA, from deep dives into the most frequently cited standards to free OSHA inspection checklists. A safe and compliant workplace is a productive one, and we’re here to help.

Getting Started

- Confused about agencies and acronyms? Check out our safety glossary.

- Want to learn more about regulatory compliance? Explore our regulations & compliance resources.

- Have a question about OSHA? Browse our OSHA Q&A hub.

- Ready to get started? Shop our selection of safety products.

OSHA Articles

NFPA 855: The Installation of Stationary Energy Storage Systems

NFPA 855 is an essential standard to follow to maintain worker safety while around stationary energy storage systems. …

Understanding OSHA/ANSI First Aid Kit Requirements

Everything you need to know about first aid kits, where they go, their contents, and why OSHA and ANSI requires them in every workplace. …

OSHA Construction Safety

Construction safety is all about picking out the right PPE, enforcing OSHA regulations, following consensus standards, and creating trust between you and your workers. …

Improving Workplace Electrical Safety

Choosing to improve worker knowledge and equipment for electrical safety creates a much safer workplace and improves overall productivity. …

How to Practice Social Distancing in Manufacturing Facilities

Social distancing and other protective measures have become a staple in occupational health and safety efforts due to COVID-19. New Social distancing guidelines from OSHA. …

OSHA Respiratory Protection Standard (29 CFR 1910.134)

Respiratory protection is essential where toxic substances are present, without PPE employees may suffer from long lasting injury or illness and even death.got …

An Introduction to Industrial Hygiene

OSHA claims industrial hygiene is the science of anticipating, recognizing, evaluating, and controlling workplace conditions that may cause workers' injury or illness. …

Preparing the Workplace with Emergency Action Plans (EAP)

An emergency action plan is a written document required by OSHA that details procedures carried out by employees during the event of an emergency. …

Understanding the OSHA 300 Log and Other Incident Paperwork

The OSHA 300 log, 300A, and 301 forms are required by law if a company meets certain criteria. These forms enable the recognition of hazards that need to be eliminated. …

Keeping Operators Safe with Machine Guarding

Machine guards are essential for facilities where employees work in close proximity to hazardous moving parts. Properly safeguarding machines prevents severe injury and death. …

Fall Protection in the Workplace: OSHA’s Guidelines

Falls are among the leading causes of work-related injuries. Learn about the fall arrest equipment you need and best practices for a fall protection program in your workplace. …

Floor Marking for Social Distancing

Using floor marking materials such as signs, tape, and other visual reminders is a highly effective way to implement social distancing and reduce the spread of illness in your facility. …

OSHA's Guidelines to Protecting Employees from Coronavirus

Learn which OSHA standards apply to preventing exposure to illness in the workplace, how to determine level of risk, and which controls to implement to protect your workers. …

Workplace Safety Inspections & Audits

Safety inspections and safety audits are two different methods of continuously improving health and safety in the workplace. Find out which one you need for effective safety management. …

Quality, Health, Safety, Environment (QHSE) Management Systems

Quality, Health, Safety, Environment (QHSE) management systems help businesses achieve three main objectives: enhanced quality, worker safety, and environmental sustainability. …

Guide to ANSI/ISEA Z358.1

ANSI/ISEA Z358.1 is the OSHA-enforced standard for eyewash stations and other equipment used to treat the eyes, face, and body of workers who have been exposed to hazardous materials. …

OSHA Incident Rates (Calculators + Formulas)

Calculating the OSHA Incident Rate and other safety rates is a useful tool for businesses to evaluate the frequency of onsite injuries and illnesses. The lower the rate, the safer the company. …

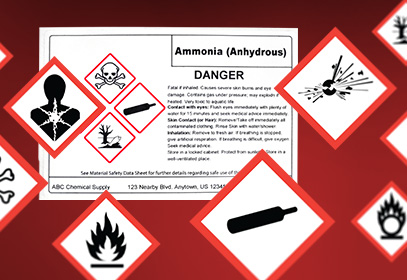

Safety Data Sheets (SDS)

Safety Data Sheets contain crucial information about the classifications and associated hazards of a chemical. They follow a standardized 16-section format and are required for any facility that handles, stores, or transports chemicals. …

Fire Safety in the Workplace

Fire safety is essential in every workplace. These are the principles that will help your facility prepare for fires and prevent them from occurring in the first place. …

Mine Safety & Health [Expert Advice]

Miners face many hazards that put their safety at risk. By adhering to MSHA standards and providing training and appropriate equipment, employers can enhance mining safety. …

Title 49: Shipping Hazardous Materials

CFR 49 notes the procedure for transporting hazardous materials safely in compliance with the HMR. Learn more about this important regulation. …

What is Heat Stress?

Are your workers at risk for heat stress? Learn how to prevent this illness and the best plan of action. …

Food Security

With the 2011 passage of the Food Safety Modernization Act, considerable attention has been focused on the purity of our foods from the perspective of accidental contamination. …

A Quick Guide to Underground Utility Labeling

Underground utility labeling is an essential ingredient to every project that involves construction. This article outlines the step-by-step process of getting your site inspected for utilities, and how to label underground lines safely and accurately. …

Your Guide to Pipe Labeling Standards

If you are looking to implement or update a pipe marking strategy for your facility it is important to gathering as much information as possible. Read More... …

OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]

OSHA regulations require businesses to follow one of two safety sign standards to remain in compliance: ANSI 1967 and ANSI 2011. Take a look at these two styles and pick the one that best meets your needs. …

What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

Hazcom is designed to help employees to quickly identify hazardous chemicals. Learn more beneficial information about Hazcom. …

A Guide to Pipe Marking Standards

For most industries, abiding by ASME/ANSI pipe marking standards is sufficient for staying safe and OSHA compliant. Some workplaces, though, are required to comply to more unique pipe marking standards due to the nature of the substance the pipes contain. …

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

SVEP – Severe Violator Enhancement Program

OSHA’s Severe Violator Enhancement Program (SVEP) was created to help ensure companies actually improve safety practices instead of just paying fines for violations. Learn how to avoid getting this designation by improving your workplace safety protocols and become a safe, efficient facility. …

OSHA Accident Reports

All companies want to avoid accidents, but an unfortunate reality is that work-related injuries happen. How a company reacts to the incident is crucial. …

Compliance Audit

Compliance audits are intended to help improve safety both for employees of the company, and for the community as a whole. Learn more about compliance audits how to prepare for them. …

Industrial Floor Marking Guidelines

OSHA doesn’t offer much guidance on how floor markings should be installed, so we’ve compiled some helpful tips and best practices to ensure your markings are useful, straightforward, and helpful to everyone in your facility. …

Hazardous Materials Identification System (HMIS Labels)

Having a complete understanding of the Hazardous Materials Identification System (HMIS) is essential to keeping your employees safe when working with chemicals. …

Occupational Safety and Health Administration

Get answers to the most common questions regarding Occupational Safety and Health Administration (OSHA). …

HAZWOPER [OSHA Hazardous Waste Standard]

Crucial training for anyone who works with or near hazardous waste, the HAZWOPER standard seeks to keep workers safe and prevent environmental catastrophe. …

OSHA Card [Program Requirements + Benefits]

The term OSHA Card refers to a type of certification that is issued from OSHA after completing authorized training that they provide. …

Hazardous Waste Disposal

Implementing proper hazardous waste disposal tools within the workplace is essential for keeping employees safe. Do you have these hazardous waste tools? …

Short-Term Exposure Limit

Short-term exposure limits are a guideline that employers can use for how long an employee can be exposed to certain chemicals before their safety is compromised. Find out more... …

Safety Audit

In a safety audit, information is gathered about one or more aspects of the workplace in order to evaluate the risk levels for health or safety issues including efficiency, reliability, and effectiveness of their health and safety systems. …

Planned Maintenance

Planned maintenance, also known as planned preventative maintenance or scheduled maintenance, is an activity where a company will schedule work done in order to avoid outages. …

ANSI S3.19 – Noise Reduction

In most facilities there is no way to eliminate dangerous levels of noise, so it becomes necessary to wear hearing protection. Hearing protection is regulated by ANSI S3.19 standards. …

Visual Factories

Visual factories use signs, posters, charts, labels and floor marking to provide information that improves efficiency, safety and productivity in the workplace. This is a fairly simple concept that yields excellent results. …

OSHA 10-Hour Card [Training Requirements]

The OSHA 10 Hour Training program teaches those in attendance all about workplace hazards, the rights and responsibilities of employees and employers, workplace safety, and more. …

NIST Certification / Calibration

NIST is a standards laboratory that is part of the U.S. Department of Commerce that certifies that the equipment used by labs or manufacturing facilities is properly calibrated according to the industry standards in place. …

ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]

ANSI Z87.1 focuses on safety glasses and helps employers and employees make decisions that can help protect people’s eyes and face from a variety of threats. …

Hazard and Operability (HAZOP Analysis)

When done properly, the HAZOP process will identify potential design or process flaws that were not discovered in the past. …

OSHA General Duty Clause

The OSHA General Duty Clause is in place to require that employers provide employees with a workplace free from any recognizable hazards that could put them at risk of death or serious injury. …

Ammonia Refrigeration

When using ammonia refrigeration, or ammonia for anything in the workplace, there are a variety of OSHA regulations that need to be followed. …

Fire Prevention in the Workplace [OSHA 1910.39]

Fire prevention safety is important for all employees and workplaces. This article explains fire prevention standards and provides helpful tips. …

OSHA Safety Sign Requirements [1910.145]

Understanding OSHA standards for warning signs and tags is an essential part creating a safe work environment. …

ANSI Color Codes for Pipe Marking

When following the ANSI A13.1 standards, the most important thing is to understand the six most common color schemes. …

OSHA Ear Protection Requirements (Standards for Hearing Safety)

Many people don't think about hearing protection when we talk about safety, but hearing injuries are one of the most common types of injuries that occur in the work place. …

Typical Lockout Tagout Procedures

Find out how to use lockout tagout procedures for different kinds of energy including electrical, chemical, and pneumatic. …

GHS Label Information

A closer look at OSHA’s Hazard Communication Standard—1900.1200—and how it applies to your facility. …

Confined Space Hazards

When is it safe to work in a confined space? Get the details in this article. …

Safety Colors (OSHA Guidelines and Color Codes)

Using colors strategically makes communication in your facility more effective. Get the details about common color codes. …

ANSI Z535 [Updated Guide to Safety Signs & Labels]

An in-depth look at ANSI’s standard for safety signs and labels in the workplace. …

Floor Stickers – Your floors come alive and speak

Improve safety in your workplace by using these 10 types of floor signs. …

PPE: Personal Protective Equipment [Safety Standards]

Get an overview of common PPE requirements for the workplace including breathing protection, eye protection, and more. …

Valve Tags: Guide for Pipe Identification

Tips and recommendations for labeling the valves on your pipe system. …

Arc Flash Software helps improve Arc Flash Safety

A review of common software programs that will help you reduce arc flash hazards. …

Aisle Marking Tape – 5 Strongest Tapes You have Ever Seen!

Learn the requirements for marking aisles and the best methods for doing so. …

The Definitive Guide to Globally Harmonized System (GHS) Labeling

Implementing GHS has been an evolving process for many companies. Here's what you need to know. …

Hierarchy of Controls [Hazard Exposure + Prevention]

An explanation of the best ways to mitigate hazards: elimination, substitution, engineering controls, administrative controls, and PPE. …

Material Safety Data Sheets [How-To Guide for Upgrading to SDS]

Learn the difference between the old material safety data sheets and the new GHS/HazCom safety data sheets. …

Pipe Color Codes - ANSI/ASME A13.1

The ANSI/ASME A13.1 pipe marking color code explained. …

OSHA Facts

Everything you need to know about the Occupational Safety and Health Administration. …

What are ANSI standards?

The American National Standards Institute makes guidelines that could impact your workplace. …

Arc Flash [Facts, Safety Requirements & PPE]

Arc flash can cause serious damage to people and property. Learn how arc flash works and how you can prevent it. …

OSHA Floor Marking

Find out what OSHA has to say about marking your facility's floors. …

Process Safety Management

PSM is an OSHA standard developed for companies that handle hazardous chemicals. …

Floor marking comprehensive research, education and training

Everything you need to know about marking your facility’s floors. Types of markings, practical tips, and more. …

OSHA Questions and Answers

Who is responsible for organizing the workplace?

Organizing the workplace is a team effort that involves everyone in the company. From the top down, each person has a role to play in ensuring that the workplace is organized and efficient. Here are some of the people who are typically most involved in organizing the workplace: Management: Management is responsible for setting the overall… …

What Does OSHA 30 Cover?

OSHA 30 is a training course that covers a range of topics related to occupational safety and health. It is designed to provide workers and supervisors with the knowledge and skills they need to identify and prevent workplace hazards, and to understand their rights and responsibilities under the Occupational Safety and Health Act (OSHA). The course… …

How Can I Report a Company to OSHA?

If you believe that your employer is violating OSHA (Occupational Safety and Health Administration) regulations, or if you have experienced a hazardous situation at work, you may want to report the issue to OSHA. Reporting a company to OSHA can help to ensure that the issue is addressed and that the company is held accountable… …

What is a Compliance Audit?

A compliance audit is a review of a company's operations to ensure that it is following all relevant laws, regulations, and standards. In the manufacturing industry, compliance audits are used to ensure that companies are adhering to safety, health, and environmental regulations, as well as industry-specific standards. During a compliance audit, an auditor will review the… …

How do I contact OSHA?

If you have questions about occupational safety and health, or if you need to report a hazard or violation in your workplace, you may want to contact the Occupational Safety and Health Administration (OSHA). OSHA is a federal agency that is responsible for enforcing safety and health regulations in the workplace, and it offers a… …

What Does BBP (Blood Borne Pathogen) Stand For?

BBP stands for "blood-borne pathogen." A blood-borne pathogen is a microorganism, such as a virus or a bacterium, that is carried in the blood and can cause disease. Some examples of blood-borne pathogens include HIV, hepatitis B and C, and syphilis. Bloodborne pathogens can be transmitted through contact with infected blood or bodily fluids, such as… …

What is the NIST Certification?

NIST stands for the National Institute of Standards and Technology, which is one of the largest and most respected non-regulatory federal agencies. It operates under the Department of Commerce. This agency offers certifications for various products to confirm that they have completed a complete testing process and that the claims made about the product are… …

What is OSHA 10?

OSHA 10-hour training courses provide entry-level workers in construction and general industry authorized by the Occupational Safety and Health Administration basic safety and health information. Since the agency's Outreach Training Program was initiated in 1971, OSHA has been working to provide training for hazards and outreach classes to communicate workers' rights. OSHA 10 Certification At the end… …

What agency of government is OSHA in?

The Occupational Safety and Health Administration (OSHA) is a regulatory agency of the United States Department of Labor, a cabinet-level department of the federal government headed by the U.S. Secretary of Labor. Their mission, as when signed into law, is to "assure safe and healthy working conditions for working men and women by setting and… …

What is TRIR?

TRIR stands for Total Recordable Incident Rate. Also known as Total Case Incident Rate, TRIR is a key metric for evaluating the organization’s safety performance from the past year. It is a lagging indicator created by OSHA and used additionally for comparing safety performances of organizations within a particular industry. With TRIR, the lower the… …

What does CFR stand for?

The Code of Federal regulations, also referred to as CFR, is a compilation of mandatory laws that have been created by several federal regulatory agencies. An example of one of those regulatory agencies is OSHA, one of the most familiar organizations to all those involved in the workforce. Currently, there are a total of 50… …

What types of businesses need to be OSHA compliant?

The Occupational Safety and Health Administration, or OSHA, is an agency of the federal government that is dedicated to making sure employers in the United States are safe. They are best known for making regulations designed to ensure employees are safe at work, but they do much more than that as well. Just about all… …

Why is OSHA training important?

OSHA is best known for creating and enforcing a wide range of different rules and regulations that businesses in the United States need to follow. While this is certainly a major component of what they do, it is not the full picture. OSHA also offers training to employers, employees, and others who need to learn… …

What is the relationship between CDC and OSHA?

Business owners need to follow many rules and regulations to help keep their employees safe. When looking into various workplace safety requirements, it is not at all uncommon to see references to the CDC and OSHA. Both of these are government agencies that have a lot to say about keeping people safe, but they are… …

What does HAZWOPER stand for?

HAZWOPER is an acronym that stands for OSHA’s hazardous waste operations and emergency response standard. This standard, 1910.120, establishes safe practices for handling hazardous waste and preparing for situations in which a toxic chemical or other substance is accidentally released. These events are extremely dangerous for workers and may have a serious impact on both… …

How are violations reported to OSHA?

If you see a hazard on your worksite that isn’t being addressed, or believe that your employer is violating a standard that has been established by OSHA and is applicable to your workplace, what can you do about it? OSHA has protections in place to help you report these types of violations so hazards can… …

What is OSHA's General Duty Clause?

The General Duty Clause from OSHA identifies several requirements that employers must provide for their employees related to a safe work environment. These are all general requirements that are intentionally vague so that OSHA can use them to enforce workplace safety standards in many situations. Three Clauses This section of OSHA’s requirements is 29 USC 654,… …

How are OSHA cards obtained?

Employers often require their employees hold OSHA cards. This is a card that is given out by OSHA after a person completes their Outreach Training Program’s 10-hour and 30-hour safety courses. Getting the required training, and the OSHA card, from only authorized locations is essential for ensuring everything is valid. It is also the only… …

What is HAZWOPER?

HAZWOPER is an acronym that stands for Hazardous Waste Operations and Emergency Response. Proper HAZWOPER safety and training is essential for a wide variety of industries, as hazardous waste is commonly generated and you don’t necessarily have to work at a waste site to come into contact with hazardous substances. These substances include batteries, paints,… …

Can OSHA eliminate hazards in the workplace?

The firs way OSHA works to eliminate hazards in the workplace is by developing standards regarding fire hazards, chemical hazards, etc. that employers have to adhere to in order to be in compliance. OSHA has recommended practices for safety and health programs, including effectively reducing hazards in the workplace with the Hierarchy of Controls. The… …

What OSHA training is required?

There are a handful of trainings that is required to all employees, no matter their job or sector they are working in. All employers are required to train workers on accident prevention signs and tags, the facility’s emergency action plan, and the fire prevention plan. All new employees also must be trained for these as… …

How does OSHA affect a business?

All employers need to thoroughly understand the applicable regulations and standards that will affect their workplace. The following are a handful of ways that OSHA can affect a business. Inspections: Inspections are a way for OSHA to enforce their regulations and standards. These inspections are not random but rather the agency conducts inspections based on… …

Who is OSHA meant to protect?

OSHA is an agency under the United States Department of Labor, responsible for occupational safety, wage and hour standards, and reemployment standards just to name a few. The primary focus of OSHA is to protect employees in the workforce and to reduce the number of deaths, injuries, and illnesses in the workplace. OSHA works to… …

What records does OSHA require an employer to have on hand?

Employers are required to keep a record of serious work-related fatalities, injuries, and illnesses. OSHA requires these records (the OSHA 300 Log, the privacy case list, the annual summary and the OSHA 301 Incident Report Forms) to be maintained at the worksite for a minimum of five years. Find OSHA’s general recording criteria here. There… …

What does it mean to be OSHA compliant?

Being compliant with OSHA means to adhere to all applicable regulations that have been developed. The following is a list of standards that must be followed by employers in order to keep the workplace safe and reduce the number of illnesses/injuries of workers. These standards are pertinent to most private sector employers as well as… …

What OSHA posters are required?

The main poster required to be displayed in a workplace is the mandatory OSHA poster. OSHA offers this poster for free as well as a high-resolution printable document. The poster is titled “OSHA Job Safety and Health: It’s the Law” and goes into detail regarding an employee’s rights and the employer’s obligations to a safe… …

How does OSHA work?

Under the agency of OSHA, workers have the right to a safe workplace free from serious hazards. OSHA has set and developed regulations to ensure workers are kept safe while on the clock. These standards are primarily enforced through inspections. During these inspections, compliance officers will tour and evaluate the facility as well as review… …

What are OSHA's requirements when it comes to PPE?

Personal protective equipment is essential to keeping workers safe from hazards on the job. Employers are required, by OSHA law, to provide properly fitting and effective PPE to workers at no cost to them. OSHA considers PPE be to be used as a “last line of defense” in the hierarchy of hazard control but requires… …

What is an OSHA card?

Did you know companies that have their employees get an OSHA card are more likely to have reduced accidents and injuries? An OSHA card refers to the card an employee will receive upon completing either a 10-hour or 30-hour Outreach Training Program, course focused on learning about improving safety in the workplace. This training may… …

How does OSHA conduct inspections?

OSHA inspections are conducted by a compliance safety and health officers and are often unannounced visits. The following is a usual procedure of an OSHA inspection: Preparation and presentation of credentials: Before the inspector conducts the inspection, he or she will research inspection history of the worksite and review the operations and processes in use.… …

Why is OSHA such an important association?

Did you know thousands of employees die from workplace hazards every year, and millions of workers suffer from an occupational illness or injury? And this is with OSHA! OSHA’s mission at its core is to ensure safe and healthful working conditions for workers all across America. They work to achieve this mission by setting standards,… …

What happens if you violate an OSHA standard?

OSHA enforces their standards through inspections and assessing fines for the violations found upon inspection. Enforcing standards through citations and fines are a part of OSHA’s core mission to reduce workplace injuries, illnesses, and fatalities. The following are levels of violations with the corresponding penalty amounts as most recently updated by OSHA: De Minimis Violation:… …

Are OSHA inspections random?

OSHA enforces their regulations primarily through compliance safety and health officers conducting inspections in workplaces. These inspectors are experienced and trained industrial hygienist professionals that assures compliance with OSHA requirements. OSHA states that the majority of inspections conducted without advanced notice. Because there are more than seven million workplaces in OSHA’s jurisdiction, it is impossible for… …

When was OSHA developed?

President Richard Nixon signed the Occupational Safety and Health Act on December 29, 1970 effectively establishing OSHA as a governmental agency. The act and OSHA itself became effective April 28, 1971 and OSHA was officially formed. Between May 1971 and May 1972, OSHA adopted the existing national consensus and established Federal standards as a baseline… …

Are OSHA regulations considered the law?

Workers are entitled to a safe workplace under federal law, and in turn employers must comply with OSHA standards and provide employees with a workplace that does not have any serious hazards. OSHA can enforce their regulations by conducting scheduled inspections or inspections following a serious injury or fatality in the workplace. Regulations that are… …

What does OSHA stand for?

OSHA is an acronym for the Occupational Safety and Health Administration, a governmental agency part of the United States Department of Labor. The agency was established under the Occupational Safety and Health Act, an act signed into law by President Nixon in 1970. The majority of private sector and employers are covered by the OSHA… …

![Mine Safety & Health [Expert Advice]](https://www.creativesafetysupply.com/content/images/articles/mining-safety-th.jpg)

![OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]](https://www.creativesafetysupply.com/content/images/articles/ansi-sign-headers-th.jpg)

![HAZWOPER [OSHA Hazardous Waste Standard]](https://www.creativesafetysupply.com/content/images/articles/hazwoper-thumb.jpg)

![OSHA Card [Program Requirements + Benefits]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-osha-10-card.jpg)

![ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ansi-safety-glasses.jpg)

![Fire Prevention in the Workplace [OSHA 1910.39]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-fire-prevention.jpg)

![OSHA Safety Sign Requirements [1910.145]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-warning-signs-tags.jpg)

![ANSI Z535 [Updated Guide to Safety Signs & Labels]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ansi-z535.jpg)

![PPE: Personal Protective Equipment [Safety Standards]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ppe.jpg)

![Hierarchy of Controls [Hazard Exposure + Prevention]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-hierarchy-hazards.jpg)

![Material Safety Data Sheets [How-To Guide for Upgrading to SDS]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-msds-sds.jpg)

![Arc Flash [Facts, Safety Requirements & PPE]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-arc-flash-facts.jpg)