Resources

HazCom is the action of passing along important and accurate information about toxic chemicals and hazardous substances. Those manufacturing and distributing hazardous chemicals must pass along safety information and in turn, employers are required to have labels and documents communicating that information to workers.

Hazard communication has been standardized by a number of different organizations and institutions over the years. Today, the Globally Harmonized System of Classification and Labelling of Chemicals is the internationally agreed-upon HazCom standard, and facilities have the option to adopt supplementary standards.

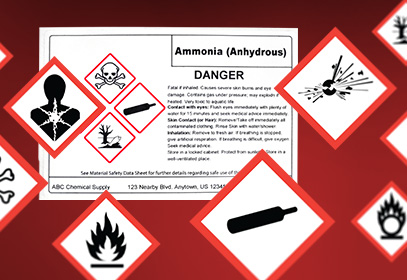

- GHS: As the leading international system for hazard communication, GHS provides a comprehensive framework for the classification of chemical hazards, standardizing chemical labels and Safety Data Sheets. GHS has been adopted by institutions and government agencies worldwide; OSHA's Hazard Communication Standard has been aligned with GHS since 2012.

- HMIS: The Hazardous Materials Identification System is a voluntary system developed by the American Coatings Association. HMIS-compliant labels feature color bars or color diamonds to communicate what types of hazards are present, e.g. blue represents health hazards, red indicates flammability, and so on.

- NFPA 704: NFPA 704 is a system for labeling hazardous materials developed specifically for emergency responders. NFPA hazard diamonds are similar to HMIS labels, featuring four different colors representing four different types of hazards and like HMIS, NFPA 704 is a voluntary system meant to aid compliance.

Effective hazard communication allows employers to design adequate safety and health programs, ensuring the right employee protections are in place, and provides the necessary hazard information to workers. Creative Safety Supply is dedicated to helping organizations create a safe workplace and we've gathered blogs, articles, infographics, and other resources for everything you need to know about HazCom.

Getting Started

- Confused with safety acronyms and technical terms? Browse our safety glossary.

- Want to learn more about GHS? Explore our GHS resources.

- Have a question about HazCom? Check out our HazCom Q&A hub.

- Ready to get started? Shop our selection of chemical safety supplies.

Hazcom Articles

Addressing Biohazard Safety in the Workplace

Biohazards consist of bacteria, virus, and fungi pathogens, as well as parasites. Remembering to provide the correct equipment, training, and visual communication is essential. …

OSHA's Guidelines to Protecting Employees from Coronavirus

Learn which OSHA standards apply to preventing exposure to illness in the workplace, how to determine level of risk, and which controls to implement to protect your workers. …

Safety Data Sheets (SDS)

Safety Data Sheets contain crucial information about the classifications and associated hazards of a chemical. They follow a standardized 16-section format and are required for any facility that handles, stores, or transports chemicals. …

Title 49: Shipping Hazardous Materials

CFR 49 notes the procedure for transporting hazardous materials safely in compliance with the HMR. Learn more about this important regulation. …

What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

Hazcom is designed to help employees to quickly identify hazardous chemicals. Learn more beneficial information about Hazcom. …

A Guide to Pipe Marking Standards

For most industries, abiding by ASME/ANSI pipe marking standards is sufficient for staying safe and OSHA compliant. Some workplaces, though, are required to comply to more unique pipe marking standards due to the nature of the substance the pipes contain. …

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

SVEP – Severe Violator Enhancement Program

OSHA’s Severe Violator Enhancement Program (SVEP) was created to help ensure companies actually improve safety practices instead of just paying fines for violations. Learn how to avoid getting this designation by improving your workplace safety protocols and become a safe, efficient facility. …

OSHA Accident Reports

All companies want to avoid accidents, but an unfortunate reality is that work-related injuries happen. How a company reacts to the incident is crucial. …

Hazard Pictograms (GHS Symbols)

More than crude drawings, these nine illustrations protect millions of people throughout a variety of industries each and every day. …

HAZWOPER [OSHA Hazardous Waste Standard]

Crucial training for anyone who works with or near hazardous waste, the HAZWOPER standard seeks to keep workers safe and prevent environmental catastrophe. …

Creating a Visual Workplace

Creating a visual workplace can help improve efficiency and reduce workplace injuries. Check out these tips for creating a visual workplace. …

Warehouse Management

Proper warehouse management can dramatically improve both efficiency and safety. This article covers everything you need to know. …

Hazardous Waste Disposal

Implementing proper hazardous waste disposal tools within the workplace is essential for keeping employees safe. Do you have these hazardous waste tools? …

Understanding the NFPA 704 Diamond Labeling System

Learn how to properly label hazardous materials following NFPA 704 labeling standards. …

GHS Label Information

A closer look at OSHA’s Hazard Communication Standard—1900.1200—and how it applies to your facility. …

The Definitive Guide to Globally Harmonized System (GHS) Labeling

Implementing GHS has been an evolving process for many companies. Here's what you need to know. …

Process Safety Management

PSM is an OSHA standard developed for companies that handle hazardous chemicals. …

GHS Label Creation

Find out how to make Globally Harmonized System (GHS) labels in 3 steps. …

Hazcom Questions and Answers

What is the New Name for MSDS?

Material Safety Data Sheets (MSDSs) are documents that provide information about the hazards, properties, and handling of a chemical or hazardous material. In 2012, the United Nations (UN) adopted a globally harmonized system for classifying and labeling chemicals, known as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). As part of this… …

Who Provides MSDS/SDS Sheets?

A Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) is a document that provides information about the hazards, properties, and handling of a chemical or hazardous material. MSDSs and SDSs are typically required by law in many countries and must be made available to employees and other users of hazardous materials. The responsible party… …

How Many Sections are in an SDS?

Safety Data Sheets (SDSs) are standardized documents that provide information about the hazards, properties, and handling of a chemical or hazardous material. There are 16 sections in an SDS, each of which provides specific information about the substance. The sections are as follows: Identification Hazard Identification Composition (also called information on ingredients) First-Aid Measures Fire-Fighting… …

What is the Purpose of SDS?

A Safety Data Sheet (SDS) is a document that provides information about the hazards, properties, and handling of a chemical or hazardous material. The purpose of an SDS is to help employees and other users understand the potential risks associated with a hazardous substance and to provide guidelines for how to safely use, store, and… …

What Does Hazmat Stand For?

Hazmat, which is commonly written as HAZMAT, stands for Hazardous Materials. It is a term that is often used when discussing workplace safety. Many factories, manufacturing facilities, shipping companies, and other types of companies need to use, store, or ship dangerous chemicals and other materials that can be hazardous in one way or another. When… …

What Does HAZCOM Stand For?

HAZCOM, which is often seen written as HazCom, stands for Hazardous Communication. In most cases, this term is used when discussing OSHA’s Hazardous Communication Standards, which are various regulations that cover information on how various chemicals must be labeled. It will also be used when discussing workplace safety related to these types of chemicals. Anytime a… …

Who Needs Hazmat Training?

If you have a facility that uses dangerous chemicals or other things, you need to make sure that they are stored, shipped, and used in a way that is safe for everyone. In addition, you need to make sure that you have people on your team who can work directly with the materials if it… …

What Does RTK (Right-to-Know) Stand For?

When dealing with hazardous chemicals and other dangerous things in the workplace, employers have a lot of responsibilities that they need to adhere to. Many of them are put in place by OSHA and are there to help keep employees safe when working in hazardous areas. When learning about the different requirements that employers have… …

Is All of the Necessary Information Included on the MSDS?

When working with or around any type of hazardous chemical, you need to make sure that you are doing everything properly to maintain a safe environment. This, of course, will start by having good safety policies and procedures in place so that a spill or other type of accident does not occur. Just as important,… …

Why Do Some MSDSs Look So Different?

When looking at material safety data sheets, or MSDSs, you may notice that they don’t all look the same. This often seems odd to many people because when it comes to safety information, most things try to fit into specific standards so that they can be used easily across multiple different industries. The reason why… …

Can an MSDS be Too Old?

Most safety professionals know that it is required to have a material safety data sheet, or MSDS, available on site for every hazardous chemical that is in the facility. These sheets include a lot of key information that will help those in the area to know the risks and know how to stay safe when… …

Do Employers Have Responsibilities for MSDS?

There are many things that employers need to do to keep their workplace safe. One of those things is to make sure that they have MSDS, or material safety data sheets, on hand for all of the chemicals that they have in the facility. These sheets must be present for all the different hazardous chemicals… …

What are Some Hazcom Training Tools?

Training employees in the hazcom (Hazardous Communications) program is extremely important. When done properly, employees will have a good understanding of what chemicals are used in the facility, what hazards they have associated with them, and how to stay safe. In addition, they will know how to look up additional information about each chemical so… …

Are Hazcom and GHS the Same?

When working on workplace safety related to chemicals, you undoubtedly see hazcom and GHS referenced together quite frequently. Many people think that hazcom and GHS are the same thing, but that is not the case. Understanding what each of these concepts is and how they can be used to keep the workplace safe is very… …

What is Non-Potable Water?

Non-potable water is any type of water that is not suitable for human consumption. There are many reasons why water may be non-potable, including that it has not been purified, it has certain contaminants, it is not protected from exposure to various things, and much more. It is also important to note that not all… …

How are corrosives hazardous to human health?

When working on improving workplace safety, you will undoubtedly see lists of hazardous substances that are listed as dangerous because they are corrosive. A corrosive substance is typically listed this way because it can corrode other materials, including metals. This makes many people wonder how corrosives are hazardous to human health. To put it simply, corrosives… …

Are there non-health-related hazards associated with corrosives?

When working on improving safety in the workplace, you must evaluate whether your facility uses corrosives for anything in the area. If so, you need to make sure that you have proper safety measures associated with them. This is mainly because they can cause such serious health problems to anyone exposed to them, and those… …

What does LD50 mean?

When evaluating hazardous substances and materials it is important to know at which point something becomes lethal. One of the ways that this is measured is commonly referred to as LD50, which stands for a lethal dose of 50%. When a set amount of a substance is given to a control group and fifty percent… …

What is a substance?

Substances can often be mistaken with mixtures, when in fact they are two very separate concepts when it comes to chemistry and hazardous chemicals. The following is a basic comparison of both substances and mixtures: Chemical Substances A chemical substance is defined as a form of matter that has a constant chemical composition and can be… …

What is a CAS registry number?

The CAS registry number, also known as a CASRN or simply CAS number, identifies a wide variety of chemical substances with a sequence of random digits. Created by the Chemical Abstracts Service, this unique number can have up to ten digits. There are up to 1 billion number sequences that can be chosen to label… …

Why is the CAS number important?

Originally, CAS numbers weren’t required to appear on Material Safety Data Sheets. Back then, MSDSs were not formatted in a way that allowed for maximum utility. Once OSHA made the Globally Harmonized System of Classification and Labeling of Chemicals required for all businesses that handled hazardous chemicals, the chemical information requirements changed rapidly. This improvement… …

How does OSHA define a hazardous chemical?

OSHA defines a hazardous chemical as “any chemical which is classified as a physical hazard or a health hazard, a simple asphyxiant, combustible dust, pyrophoric gas, or hazard not otherwise classified.” Furthermore, OSHA clarifies chemical hazards and toxic substances pose a wide range of health hazards (like irritation to the skin) and physical hazards (such… …

What is the difference between MSDS and SDS?

Material safety data sheets (MSDS) was the required documentation for hazardous chemicals before OSHA aligned with the Globally Harmonized System of Classification and Labeling (GHS). After its adoption in 2012, businesses that handle, store, and use dangerous chemicals must follow the guidance specified for safety data sheets (SDS). Prior to these major changes in the Hazard… …

What information is on an MSDS?

Material safety data sheets (MSDS) are important documents that contain information about hazardous chemicals in the workplace. These are a part of the globally harmonized system of classification and labeling of chemicals (GHS) and provide detailed information that can help people to learn about the various chemicals. These informative sheets are required for safety compliance… …

What does HCS stand for?

HCS stands for Hazard Communication Standard. This standard requires that hazardous material information must be available for employees and people such as emergency response personnel because they have the right to know what kinds of hazards are present and how to then protect themselves. Hazard information should be available through the following means: Training Visual… …

What is MSDS?

A Material Safety Data Sheet, often referred to as an MSDS, holds pertinent information about the physical properties of a hazardous substance. However, the term MSDS has been changed to SDS, Safety Data Sheet, in recent years. This type of document is required by OSHA under the Hazard Communication Standard (HCS) in 29 CFR 1910.1200(g).… …

What does WHMIS stand for?

WHMIS is an acronym that stands for, “Workplace Hazardous Materials Information System.” It is there to provide important information on things that could impact safety and health of employees in the workplace. This system is the national workplace hazard communication standard for Canada. While it is primarily used in Canada, companies that provide goods and… …

What is HMIS?

HMIS is an acronym that stands for Hazardous Materials Identification System. It is a hazard rating system that uses numbers as well as colors to make it easy for people to understand what type of dangers there is with chemicals. This system was developed by the American Coatings Association. They originally developed it to help… …

What is a pictogram?

Pictograms are used in many different situations, including workplace safety. They are generally described as a simple visual representations of data; some people also call them icons or pictorial unit charts. In many cases safety pictograms are black and white, though they can be colored as well. These are very popular because they can convey… …

What does IMDS stand for?

IMDS stands for International Material Data System. It is a repository of data that is used to share information on all the different materials that are commonly used in the automotive industry. This data repository was first introduced in June of 2000 and was developed by several top auto manufacturers including Audi, BMW, Daimler, EDS,… …

What is the purpose of MSDS?

An MSDS, or Material Safety Data Sheet, is a document that provides information about a specific chemical or substance. These documents are required to be stored in any facility where the chemical is used. The purpose of MSDS is to provide specific information related to the chemical so that those who need to know about… …

What is HazMat?

“Hazmat” is an abbreviation for hazardous materials. These materials are regulated by several different government agencies, which each have their own definition for what counts as a hazardous material: OSHA The Occupational Safety and Health Administration defines a hazardous material as any substance that presents a physical or health hazard. These substances include corrosive chemicals, combustible… …

What does MSDS stand for?

MSDS stands for Material Safety Data Sheet. An MSDS is a document that contains information related to a potentially hazardous material that is found in a given workplace. MSDS is sometimes referred to simply as SDS (Safety Data Sheet) or PSDS (Product Safety Data Sheet). No matter what acronym is used, these documents are important… …

How often is HazCom training required?

The HazCom program is a great way to improve workplace safety when there are dangerous chemicals being used. The system was originally developed to help ensure employees were given all the information they need about the dangers associated with working with or near chemicals, it has really evolved into more than that. Still, at its… …

What are different types of hazard communication?

When preparing to implement a HazCom system in a facility, it is important to learn about the different options. There are multiple different types of HazCom labels and other tools that need to be used in order to maximize safety in the facility. Providing employees with the necessary training on all aspects of a hazardous… …

What are safety data sheets?

Safety data sheets (SDS) are informational documents that companies keep on hand for each potentially hazardous chemical in a facility. The information contained within a safety data sheet is standardized so that those reading it will be able to get accurate information about the chemical in question. SDS’s were made to comply with OSHA rules… …

Why is HazCom important?

Over the past several generations, society has grown to understand the importance of workplace safety. During this time, most workplaces have also recognized that a safe work environment is also going to be a more profitable one. Whether by choice, or through regulations, companies have taken dramatic steps to help improve the overall safety of… …

Who in the workplace must have HazCom training?

The HazCom standard was developed by OSHA to help provide employees with the information they need to know when it comes to chemical safety in the workplace. Employers who have positions where employees work with or around chemicals are required to provide them with information about the physical hazards of the chemicals as well as… …

Who regulates HazCom?

HazCom was developed based on OSHA’s ‘Right to Know’ program, which guarantees workers have the right to know about any potentially dangerous chemicals that they are working with. OSHA continues to develop and enforce this set of safety standards for all companies in the United States. It is also important to note that OSHA makes… …

Who does HazCom apply to?

HazCom will generally apply to any company that uses, stores, or transports any type of potentially dangerous chemical. This includes companies in general industry, marine locations, longshore businesses, construction, medical facilities, shipyards, warehousing, shipping, and many others. Since HazCom was created, maintained and enforced, by OSHA, the program will really only apply to companies operating… …

When is a HazCom program required?

Any company that operates in the United States and has any type of dangerous chemicals in use will need to have a HazCom program implemented. This is required by OSHA, which is the agency that came up with the HazCom program in the first place. It was intended to make it mandatory for companies to… …

What is a HazCom program?

A HazCom program is implemented in a workplace to make sure that employees know what chemicals are used, and what dangers they present. The system is mandated by OSHA, which insists that companies must tell employees of these types of risks. With the goal of keeping employees informed about the risks they face at work,… …

What does the HazCom standard cover?

The HazCom (Hazardous Communication) standard from OSHA covers a number of important things related to dangerous chemicals in the workplace. It was developed to help ensure employees have the right to know about the dangers related to chemicals that they are likely to work with. In order to accomplish that goal, the standard has grown… …

What does a HazCom label include?

The hazardous communication standard (HazCom) issued by OSHA is an important set of processes and procedures designed to help ensure employees are aware of what chemicals they are working with. In addition, they must be informed about the potential dangers associated with the chemicals. One of the main ways that employees know about which chemicals… …

What is the HazCom standard?

HazCom is short for Hazardous Communication Standard and is a set of standards that are used to ensure that employees are aware of the dangers associated with chemicals being used in a facility. It was originally developed by OSHA as a way to make sure that employers weren’t hiding the types of dangers that are… …

How many HazCom pictograms are there?

HazCom pictograms are an easy way to convey information in the workplace when there are potentially hazardous chemicals present. These pictograms are very simple images that convey the type of hazard that a chemical possesses. There are a number of different pictograms that have been established and are used in various workplaces. Many people who… …

What are HazCom labels?

Hazardous chemicals are a part of many workplaces. Making sure that employees understand the dangers associated with each type of chemical is an important part of an overall workplace safety program. To help to ensure everyone understands what chemicals are present, what hazards are associated with them, and other important information, OSHA has come up… …

What Does HMIS Stand For?

HMIS stands for Hazardous Materials Identification System. It was created by the American Coatings Association (ACA) to help companies comply with OSHA’s chemical/hazardous materials labeling standards in the workplace. The HMIS standard provides an easy to read format that quickly imparts information, which is why it is so useful in areas where workers are exposed to… …

What is HAZCOM training and how often is it required?

HAZCOM training, also known as the OSHA Hazard Communication Standard, is designed to protect employees from hazardous chemicals in the workplace. According to OSHA, “effective training is vital to understanding the information provided on chemical container labels and material safety data sheets and applying that information in the workplace to protect against chemical hazards.” Companies… …

![HAZWOPER [OSHA Hazardous Waste Standard]](https://www.creativesafetysupply.com/content/images/articles/hazwoper-thumb.jpg)