Working with and around live energy isn't for the faint of heart. In energized environments, workers are most likely to encounter arc-flash, shock, and arc-blast hazards. It's for this reason that the NFPA 70E standard was created. This live energy-focused standard strives to keep workers safe by reducing the risks involved with electrical systems and circuits. Any business that works with live energy are required to follow NFPA 70E.

What is NFPA 70E?

The NFPA 70E standard was designed by the National Fire Protection Association (NFPA) for safety-related work practices regarding electrical energy. These requirements are designed to protect workers by reducing risks of major electrical hazards. The NFPA 70E standard stems from an OSHA request to build a standard that would help employers avoid workplace injuries and fatalities due to electricity-related accidents and helps businesses comply with OSHA standards 1910 and 1926.

NFPA 70E Vs. NEC

If you're not an electrician or electrical engineer, the various agencies in charge of different standards can be confusing. The NFPA 70E standard is a cousin of NFPA 70, the National Electrical Code (NEC). The NEC is the standard for design of electrical systems, but not how to complete the work; the NFPA 70E instructs safe work practices for electrical construction and maintenance, but not how to design electrical systems.

Since the 70E standard covers electrical safety in the workplace, it applies to every business you can think of: grocery stores, universities, cafes, libraries, etc. Despite the fact that this standard applies to countless types of industry, NFPA 70E is most often enforced in manufacturing plants, factories, warehouses, and worksites - places where electrical construction and maintenance consistently happens.

There are some big differences between the NFPA 70E and NEC when it comes to enforcing these standards. The NEC is for regulatory use and it is enforced by electrical inspectors. Since the NFPA codes are not regulatory, customers/site managers are responsible for enforcing safety practices on electrical contractors.

The scope of NFPA 70E is narrow in that its focus is solely on three kinds of hazards:

- Arc-flash

- Electrocution

- Arc-blast

These dangers are the entire purpose for NFPA 70E. Other worksite-related hazards (ladder best practices, scaffolding, hazardous material, etc.) fall under the umbrella of OSHA construction safety regulations.

The Electrical Safety Strategy

To keep your facility free of electric energy-related accidents, NFPA 70E recommends the following practices:

- Shut power down. It's important to work in a de-energized environment, though this isn't always possible.

- Get proper permit. Have person in charge (manager, foreman, customer, property management company, etc.) sign an Energized Electrical Work Permit.

- Wear PPE. Personal protective equipment (PPE) helps protect from catastrophic injury in the case of fire, electrocution, or shock. Examples of PPEs are flash suits, face shields, or flame-resistant clothing.

Power Down. Seriously.

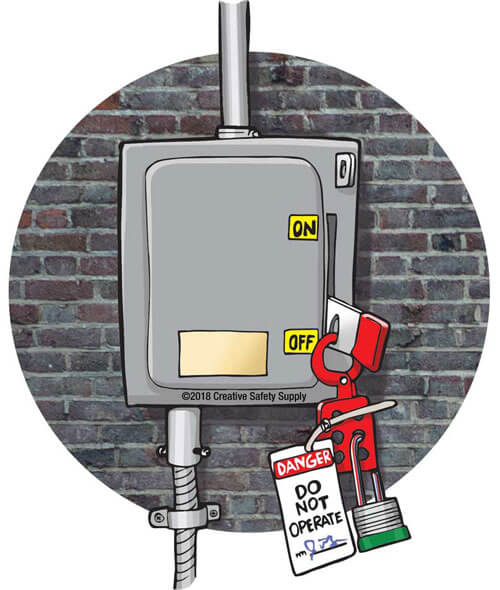

If you haven't yet implemented a Lockout/Tagout (LOTO) system into your facility, now's the time. LOTO systems help save workers from severe injuries and death. LOTO systems are simple: you use locks and tags to literally lock (when possible) power switches when maintenance is being performed. If switches cannot be locked, you place a tag over the on/off mechanism. Locks and tags inform other workers to leave the machine alone while repairs are being done.

Before you start working, double check equipment to make sure that machine isn't just turned off but completely disconnected from its source of power (pneumatics, electricity, etc.), and that there is no risk of the system releasing any stored energy.

Post Energized Electrical Work Permit

This work permit ensures that people in responsible positions (managers, customers, building owners, etc.) are educated and involved in the decision whether to accept the increased risk associated with working on energized electrical conductors or circuit parts. Working around energized power is dangerous; it's important to make sure everyone is aware of the conditions and the potential hazards involved. Posting these energized electrical work permits can lead to a decision to complete work de-energized.

Recommended PPE

These standards recommend a vast array of PPE, all of which depends on the work you will be accomplishing. For a full list of PPE, consult the NFPA 70E Handbook. The following items are a good start to protecting workers around electrical energy.

- Arc-rated, non-melting or untreated natural-fiber clothing

- Rubber insulating gloves and leather protectors

- Class G or E hard hat (if necessary)

- Face shield

- Safety glasses

- Dielectric overshoes (if necessary)

The NFPA 70E is a vital tool for staying safe and protected from shock, arc-flash, and arc-blast accidents in energized environments. Whether performing maintenance or completing electrical construction, following these standards will ensure your workers stay safe, protected, and OSHA compliant.

2018 Updates

NFPA 70E is revised every three years to reflect industry changes, evolving technologies, or new research. The 2018 edition of the electrical safety standard continued to emphasize training, focused on hazard elimination, and made formatting changes to make it more user friendly. Some major changes in the 2018 edition include:

- Risk Assessments: Human error and its negative consequences must be addressed when working through the risk assessment procedure. List specifically the impacts human error can have on people, processes, equipment, and the facility.

- Hierarchy of Controls: The Hierarchy of Risk Control Methods was moved from being an information note in previous editions of the NFPA 70E to being in the standard’s mandatory text. This means employers are required to work through the hierarchy when addressing hazards and elimination must always be prioritized.

- Choosing Arc-Rated Clothing: Due to newly included Hierarchy of Controls, PPE must be considered the “last resort” of protection.

- Arc Flash Assessments: Because of the addition of the Hierarchy of Hazard Controls, the PPE-required table was modified to list the likelihood that an arc flash would occur. This table scan now be used as a means for performing a risk assessment.

- Training: The 2018 update now states employees must be retrained if their job duties change or when procedures are not being followed.

Another update the 2018 revisions brought was addressing who is responsible electrical safety. Previously, employers held sole responsibility for compliance. The 2018 edition of NFPA 70E acknowledges a workplace free from electrical hazards requires a collaborative effort between both employers and employees. While employers must establish, document, and provide training, workers have the responsibility to comply with the safety procedures and rules provided to them.

2021 Updates

There were only a handful of changes made for the 2021 edition of NFPA 70E. The changes create clearer responsibilities when working around this kind of dangerous environment, they are as follows:

- General Requirements: Article 110 was changed to include the general requirements for electrical safety-related work, programs, practices, and procedures from other articles.

- Arc-Resistant Equipment: Arc-resistant switchgear was changed to arc-resistant equipment in both table 130.5© and 130.7©(15)(a) for the term to be able to include all types of arc-resistant equipment.

- Safety-Related Requirements for Capacitors: Article 360 and Annex R, both of which reference capacitor requirements, were added to address their unique safety requirements.

- Arc-Flash Boundary Calculation Methods: Annex D, which references the calculation methods for both incident energy and arc-flash boundary calculations, was changed to match calculation methods depicted in IEEE-1584-2018.

All of these new additions are important to be familiar with moving forward as they will ultimately protect employees working in environments involving dangerous electrical tasks.

Similar Articles

- NFPA 855: The Installation of Stationary Energy Storage Systems

- NFPA 99: Understanding the Health Care Facilities Code

- NFPA 25: Standards for Fire Protection Systems

- NFPA 704

- Understanding the NFPA 704 Diamond Labeling System

- Lockout/Tagout Program (How To Control Hazardous Energy)

- Arc Flash Label Requirements [2018 Updates]

- Arc Flash PPE

- Improving Workplace Electrical Safety