Single-minute exchange of die is the process of trying to make changeovers as fast as possible. Quickly changing a process so that it can go from making one product to making another helps reduce lead times and inventories and facilitate one-piece flow production. (However, bear in mind that the phrase "Single Minute" does not necessarily mean that all changeover, setup, and startup times should take only one minute. Rather, the name is meant to stress the need that changeover, setup, and startup times should take less than 10 minutes; in fact, “single minute” is short for "single digit minute." SMED has a better ring to it than SDMED.)

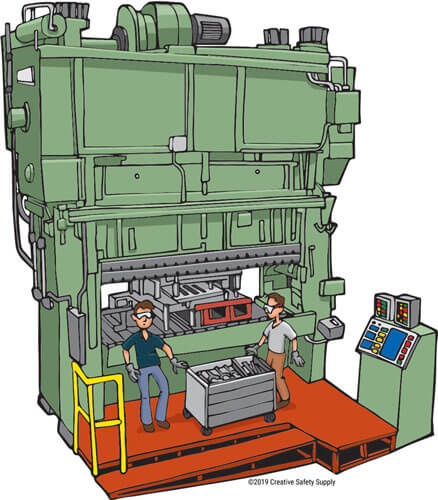

The term die refers to a tool used in manufacturing to form materials, but the concept of SMED can apply to many work environments. Any time setup needs to occur before a process begins can be optimized with SMED. Manufacturing environments will be the obvious choice for SMED implementation, but most work environments—fast food restaurants, offices, call centers, etc.—have certain processes that need to happen before workers can perform their duties. This is where SMED implementation can optimize tasks and improve production and productivity.

The term die refers to a tool used in manufacturing to form materials, but the concept of SMED can apply to many work environments. Any time setup needs to occur before a process begins can be optimized with SMED. Manufacturing environments will be the obvious choice for SMED implementation, but most work environments—fast food restaurants, offices, call centers, etc.—have certain processes that need to happen before workers can perform their duties. This is where SMED implementation can optimize tasks and improve production and productivity.

Think of a pit crew at a NASCAR race. This trained crew knows how to remove the old tires and put on the new ones as quickly as possible. Ideally, changeovers in the workplace will be coordinated and performed like this.

When a business tries to reduce changeover times, people should assess what parts of the changeover can occur while production is running and what parts must occur while the process is completely stopped. Reducing the number of steps that have to occur while production is stopped is a good way to reduce changeover times.

Implementing Single Minute Exchange of Die (SMED):

Single Minute Exchange of Die (SMED) was first introduced by a Japanese quality management pioneer by the name Shigeo Shingo. A world-leading industrial engineer and expert on the Toyota Production System, Shingo is a celebrated pioneer in Lean manufacturing. The esteemed Shingo Prize was named after him. Shingo developed SMED after discovering that the process of replacing the dies on transfer-stamping machines took from twelve hours to nearly three days to complete. Shingo recognized that there are eight main techniques that should be considered when implementing SMED. However, note that external setup can be done without the line being stopped, whereas internal setup needs the line to be stopped.

- Separate internal from external setup operations

- Convert internal to external setup

- Standardize function, not shape

- Use functional clamps or eliminate fasteners altogether

- Use intermediate jigs

- Adopt parallel operations

- Eliminate adjustments

- Mechanization

Effects of Implementing Single Minute Exchange of Die (SMED):

So, how effective is the implementation of Single Minute Exchange of Die (SMED) to a manufacturing process? Basically, SMED and quick changeover programs have many benefits for manufacturers, from reducing downtime associated with the changeover process to reducing the waste created during start up. Additional benefits include:

- SMED increases machine work rates from reduced setup times even if number of changeovers increases

- It eliminates setup errors while allowing trial runs to reduce defect rates

- Improved quality from fully regulated operating conditions in advance

- Increased safety from simpler setups

- Simplified housekeeping from fewer tools and better organization

- Stockless production drives a company’s capital turnover rates

- Reduction in footprint of processes will reduce inventory, thereby freeing workshop space

- Productivity increases over time

- SMED lowers set up and other expense

- Skill requirements are lower since changes are now designed into the process rather than a matter of skilled judgement

- Elimination of unusable stock from model changeovers and demand estimate errors

- Goods are not lost through deterioration

- Ability to mix production gives flexibility and further inventory reductions as well as opening the door to revolutionized production methods

Similar Glossary Terms

- Changeover

- World Class Manufacturing

- Poka Yoke

- Lean Production

- Material Flow

- Taguchi Method

- Heijun-ka

- Cellular Manufacturing

- Lead Time