Process safety management (PSM) is an OSHA requirement (29 CFR 1910.119) for the safe management of highly hazardous chemicals. Highly hazardous chemicals are a list of substances determined by OSHA and the Environmental Protection Agency that have the potential to cause a catastrophic event. Because of their toxic, flammable, reactive, or explosive nature, OSHA has established a comprehensive management program to help companies safely store and handle these chemicals.

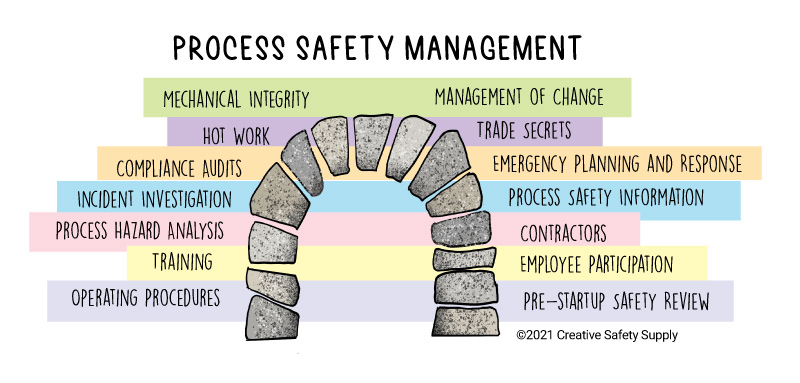

Regulations for PSM can be broken down into 14 elements as defined by OSHA. These elements are interdependent on one another and each one must be included for an effective PSM program. Many of the components contributes information or is dependent on information from another element, so every element is necessary for a comprehensive plan. The required elements are as follows:

- Operating Procedures

- Training

- Process Hazard Analysis

- Incident Investigation

- ComplianceAudits

- Hot Work

- Mechanical Integrity

- Management of Change

- Trade Secrets

- Emergency Planning and Response

- Process Safety Information

- Contractors

- Employee Participation

- Pre-startup Safety Review

Although each element plays an important role in PSM, process safety information is considered to be the cornerstone of a process safety management program. OSHA requires employers to compile all written process safety information prior to conducting a process hazard analysis. These documents provide information about the hazards posed by the highly hazardous chemical, the technology of the process, and the equipment used in the process. When it comes time to conduct a process hazard analysis, there is not one right way to do it. However, OSHA has listed a number of approved methods to choose from when completing an analysis including fault trees, a failure mode and effects analysis, a what-if checklist, a hazard and operability statement, and an appropriate equivalent methodology.

It is important employers fully understand the chemicals being used in their facility and the regulations that must be followed. When it comes to handling and storing highly hazardous chemicals, investing the time and effort to create a comprehensive program will keep workers safe and prevent potential disasters.

Similar Glossary Terms

- Safety Data Sheets (SDS)

- Chemical Safety

- GHS

- Safety Management Plan

- Fire Prevention Plan

- HAZCOM

- HazMat

- DFMEA (Process Failure Modes and Effects Analysis)

- Leak Detection and Repair (LDAR)